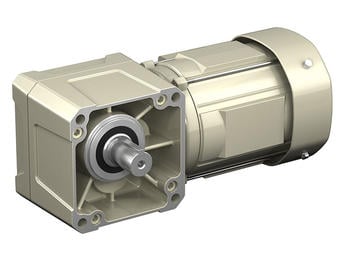

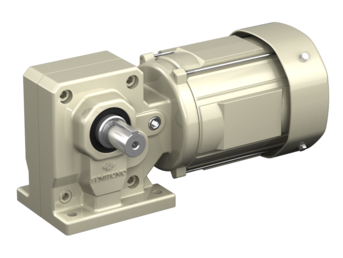

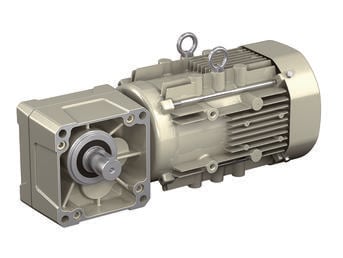

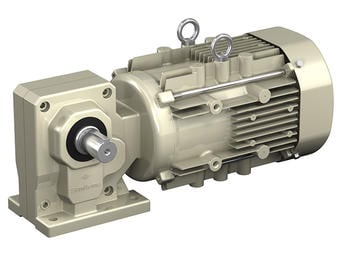

HYPONIC® Gearmotor

Right angle shaft gearmotor, with a motor range of 1/8 to 15 HP

- Maintenance-free grease lubrication eliminates oil changes

- A wide range of choices ( 1/8 to 15 HP ) to accommodate all types of uses.

- Modular design allows for multiple gearheads and motor combinations for increased service factor.

- A variety of industry packages and options are available, including grease lubrication, antibacterial coating, waterproofing, and low-temperature requirements.

| Output Shaft | Hollow shaft, Solid shaft |

| Output Shaft Direction(s) | Any Mounting Direction |

| Mounting Style | Shaft mount, Foot mount, Flange mount |

| Frame Size | 12 sizes |

| Reduction Ratio | 5:1 - 1440:1 |

| Capacity | 1/8 to 15 HP |

| Motor Types | Three phase, premium efficiency, high efficiency, for inverters, single phase, outdoors, waterproof, increased safety, compliant with overseas standards |

Product Features

CAD / Configure

Select your level of product detail:

Learn more about our CONFIGURATOR TOOL:

I don’t like the turnbuckle torque arms and sometimes have reversing applications they don’t work well for, do you have another option?

Yes, we have 6 different torque arm options to make your installation easy.

What if I need to change the backstop rotation?

No problem, your Sumitomo rep can assist with that, we can instruct you how, or you can send it to us to do.

Can I adjust the speed with a direct drive like I can with a belt drive?

Not by changing a sheave size since that component is eliminated, but there are things to consider…

- How often are you really changing the speed?

- The flexibility of changing a sheave size also puts your system at risk. Are you overspeeding beyond the reducer's capabilities? Are you slowing down too much and causing the backstop spragues to drag and wear?

If you are utilizing a VFD, that can control your speed.

- If you find out you truly need to change your speed, our BBB is the only direct drive on the market that has a Cyclo cartridge that could be changed to change your overall speed eliminating the need for a whole new reducer. Work with your Sumitomo rep to consider this.

My motor is a footed motor on my belt drive system, do I have to get a new motor for the direct drive?

No, you can order a c-face transition kit from your motor manufacturer and turn a footed motor into a c-face motor very easily. We have other options we can provide if you absolutely can not replace or change your motor to a c-facemotor.

I don’t have a very long shaft, can I still replace a belt drive with a direct drive?

Yes, if our standard Taper Grip Bushing requires more shaft than you have, we have a new Taper Grip Bushing option that needs an average of ½ the shaft length. When we size up the reducer you need, we can tell you how much shaft length you need for both options.

What should be some features or upgrades I should consider for the Aggregate, Sand and Cement industries?

Taconite Seals, Severe Duty or Desiccant Breather

There are many accessories for use with the Helical Shaft Mount (HSM). Our patented Taper Grip Bushing is well suited for any application. A motor mount, backstop, torque arm, ABS belt guard, belts, breathers, sheaves and harsh duty seals are all accessor

Do you supply a torque arm? At what position should it be mounted? A torque arm assembly is offered as an option. The standard torque arm assembly and standard mounting positions are shown in the Appendix of our catalog.

What is the efficiency of a hypoid reducer?

A hypoid reducer is more efficient than the traditional worm gear reducer. The reason why a hypoid gear is more efficient than a worm gear is due mainly to two factors: gear tooth profile and the material it is made of. Hypoid gear is all-steel, while worm gear uses steel and a bronze wheel (that will wear down).

What is meant by load centering?

The reducer’s radial load capacities are calculated at the midpoint of the slow speed shaft extension. Radial load capacities decrease if the center of the load is moved farther from the reducer and the values obtained must be adjusted accordingly. Refer to the Special Load Guidelines section in the Appendix of our cagtalog for load location factors.

Should overhung load and thrust load be considered when making a selection?

Yes, loads imposed on the slow speed shaft will vary according to the method used to connect the shaft to the driven machine. Frequently, in addition to the torsional forces, radial (overhung) and thrust loads are applied to the slow speed shaft at the same time. For example, coupling connections normally involve torsional forces only. However, when power is transmitted through spur gears, belts, pulleys, or chains, both torsional and radial forces may be present. When driving through helical or bevel gears, all three conditions (torsional, radial, and thrust load) may be referred to the reducer shaft. The slow speed shaft and bearings must have sufficient strength to withstand these loads, and it is necessary to determine the allowable limits for each condition. The Special Load Guidelines section in the Appendix of our catalog explains how to calculate the overhung load (radial) applied to the output shaft.