Sumitomo Concentric, Parallel, and Right-Angle Gearboxes

Gearboxes are a critical component of most mechanical systems, and they serve the critical function of transmitting power and torque between the motor and the driven equipment. The gearbox's shaft arrangement plays a vital role in how well it can perform this function and can impact the system's overall performance. When designing a power transmission system, selecting the right gearbox is essential to achieving efficient, reliable, and cost-effective operation.

A gearbox's shaft arrangement refers to how the gearbox's input and output shafts are arranged in relation to each other. The three primary gearbox shaft arrangements are concentric, parallel, and right-angle. Each of these designs has its unique advantages and disadvantages, and selecting the right one requires careful consideration of your application's specific requirements.

In this article, we'll provide an in-depth exploration of the different gearbox shaft arrangements and how they impact gearbox performance. We'll examine each type of gearbox's unique characteristics and discuss each's benefits and drawbacks. Additionally, we'll highlight why Sumitomo should be your go-to manufacturer for optimal gearmotor performance, offering a range of gearbox solutions suitable for a wide range of industrial applications.

What is a Concentric Gearbox?

Concentric gearboxes, also known as inline gearboxes, feature a design in which the input and output shafts are aligned on the same axis. In other words, the shafts are concentric and run parallel to each other.

This design makes concentric gearboxes ideal for applications requiring a compact, space-saving solution, as they take up less space than other gearboxes.

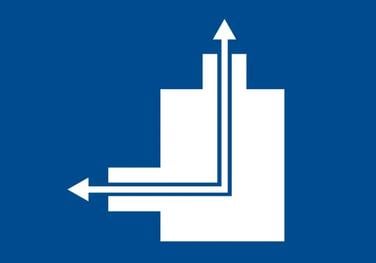

What is a Right Angle Gearbox?

Right-angle gearboxes, also known as perpendicular gearboxes, feature a design in which the input and output shafts are perpendicular to each other.

This design allows for a compact, space-saving solution that is suitable for applications with limited space. Right-angle gearboxes also offer a wide range of gear ratios, making them suitable for a wide range of applications.

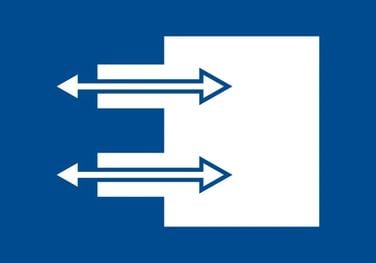

What is a Parallel Shaft Gearbox?

Parallel shaft gearmotors, also known as parallel shaft gearboxes, feature a design in which the input and output shafts are parallel to each other but offset.

This design allows for higher torque capacity and a wider range of gear ratios than concentric gearboxes, making them suitable for applications that require higher torque and speed capabilities.

Choosing the right gearbox shaft arrangement is critical to ensuring optimal performance in your industrial application.

Whether you require a space-saving solution or a high-torque gearbox, there is a gearbox shaft arrangement suitable for your specific requirements. This page explored the different gearbox shaft arrangements, including concentric, parallel, and right-angle gearboxes.

With over 100 years of experience in the industry, Sumitomo is a trusted manufacturer of gearmotors, offering a range of gearbox solutions suitable for a wide range of industrial applications. Whether you require a concentric gearbox, parallel shaft gearmotor, or right-angle gearbox, Sumitomo has a solution to meet your needs.