Food and Beverage

We offer gearmotors tailored to the unique requirements of the food and beverage industry. From extreme temperatures to caustic high-pressure wash-down environments, we provide solutions that meet your demands.

Food and Beverage Manufacturing

Governing sanitation bodies are recommending more severe bacteria control in food and beverage handling environments. Equipment utilized within food handling facilities must be capable of withstanding long-term exposure to chemical washdowns, without external degradation or compromise in performance.

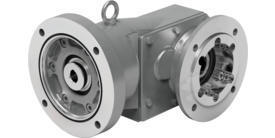

Unlike any other manufacturer, we have solutions that will meet your most stringent requirements. Our line-up of products include:

- Food grade harsh duty cassette sealing solutions

- NSF H1 food grade lubricant

- SHIELD360°® paint protection product line

- IP69K certified gear reducers

- Stainless steel gear reducers

What separates us from the competition?

Food & Beverage Brochure

Overhead Doors

Packaging Equipment

Palletizer

Proofer

Pumps

Sheeter

Shrink Wapping

Chiller

Blender

Agitators

Filler Equipment

Batching Equipment

Bottling Machines

Loaders/ Unloaders

Carousel Conveyor

Pumps

Drying Drum

Grinder

Granulator

Grass Hopper

Cane Unloader

Juice Clarifier

Juice Sulphitation Tank

Crystallizer

Centrifuge

Rotary Shaker

Case Studies

Our speed reducers are proven in millions of installations worldwide and are built to last. They are known among industry leaders as one of the best gear drives available. Take a look at companies like yours who have taken the Sumitomo challenge and tested us on their application.

Related Products

Looking for more support?

The Sumitomo team is here to help! Reach out to us today for further assistance.