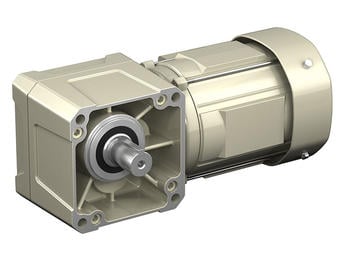

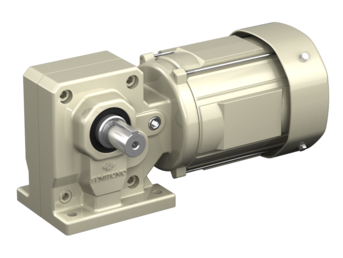

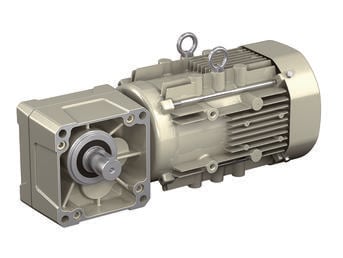

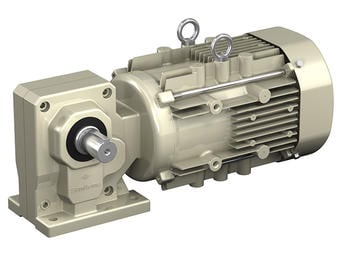

HYPONIC® Gearmotor

Right angle shaft gearmotor, with a motor range of 1/8 to 15 HP

- Maintenance-free grease lubrication eliminates oil changes

- A wide range of choices ( 1/8 to 15 HP ) to accommodate all types of uses.

- Modular design allows for multiple gearheads and motor combinations for increased service factor.

- A variety of industry packages and options are available, including grease lubrication, antibacterial coating, waterproofing, and low-temperature requirements.

| Output Shaft | Hollow shaft, Solid shaft |

| Output Shaft Direction(s) | Any Mounting Direction |

| Mounting Style | Shaft mount, Foot mount, Flange mount |

| Frame Size | 12 sizes |

| Reduction Ratio | 5:1 - 1440:1 |

| Capacity | 1/8 to 15 HP |

| Motor Types | Three phase, premium efficiency, high efficiency, for inverters, single phase, outdoors, waterproof, increased safety, compliant with overseas standards |

Product Features

CAD / Configure

Select your level of product detail:

Learn more about our CONFIGURATOR TOOL:

What information do I need to get started in the selection process?

To select the proper reducer for your application, you will need to know:Application: type of driven machine

Hours of operation per day

Motor horsepower (HP) and speed (RPM)

Loading Conditions

Mounting Position

Ambient environment (altitude, dusty, chemical, explosive, water)

Ambient temperature and humidity

You must also note any special environment factors or operation requirements. This information will ve important in determining your application's service factor.

How do I select a Hyponic® reducer or gearmotor?

Selection is based on the actual horsepower and/or torque requirements at the output shaft. The Hyponic® speed reducer has particularly high efficiencies over a wide range of reduction ratios, which frequently permits the use of reduced input power requirements (smaller HP motor) without sacrificing output shaft torque. The selection procedures in our catalog will guide you in choosing the most efficient reducer for your application.

What are the advantages of the Hyponic® reducer over other right angle drives?

Hyponic® uses hypoid gearing, which is more efficient than worm gearing and quieter than bevel gearing. It is superior within the right-angle drives.

I want to change the motor on a Hyponic® unit. How can I do this?

The Hyponic® motor cannot be replaced because the hypoid gear is controlled as a set with the motor shaft. Contact our Aftermarket Department for replacement service.

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.