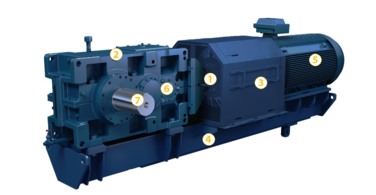

Drive Package Solutions For Your Industrial Gearbox

We offer our customers more than just an industrial gearbox.

As a reliable industrial gearbox supplier we offer complete drive packages from a single source, ensuring it meets your specific requirements. Our specialists carefully select your drive package components including supporting structures or motor adapters with couplings, brakes, motors, auxiliary drives, the right protection guards and predictive maintenance accessories. We provide flexible engineering solutions to best fit your application!

Here are some examples from which components you can choose

1 Input Shaft

Couplings or pulley drives

Various types of couplings are being used between the motor and gear unit depending on the application and properties. Popular options are disc, claw and fluid couplings or pulley drives. The flexible disc-type composite couplings are typically used in cooling technology applications. Elastic claw couplings compensate a small axial, radial and angular misalignment between both coupling hubs. Fluid couplings reduce the motor starting torque for a gentle, reliable start-up of systems with high inertia starting (e.g. conveyor or toaster drives). A pulley drive is an effective way to connect the gear unit input shaft to the motor via a belt or chain. Typically this setup is used when the motor is installed to the gear unit e.g. in applications as conveyors, screw pumps or mixers.

Brakes

Various designs are available if brakes need to be used at the input end together with the electro/hydraulic thrusters. Popular options are drum or disk brakes but also we supply specific (mobile) brake solutions for Cooling technology applications during maintenance.

Protection guards

The shaft, coupling or pulley and brake needs to operate at all times under safe conditions according to applicable standards. We can make your Protection guards according to e.g. EC Machinery Directive. Fluid couplings require an oil pan to catch the splashing oil in case of overload protection. Fan guards are designed to maximize air flow while minimizing noise.

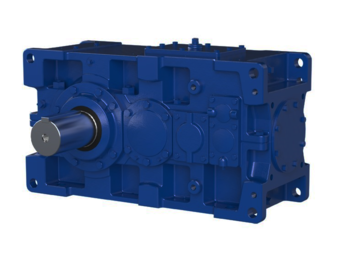

Gearbox

Perfect line up of PARAMAX range with the Hansen industrial gearbox range for horizontal and vertical applications. As a result Sumitomo Drive Technologies can offer a complete range of helical and bevel-helical gear units from 15 to 1100 kNm. Various shaft types are possible, solid and hollow output shaft including keyway and shrink disk.

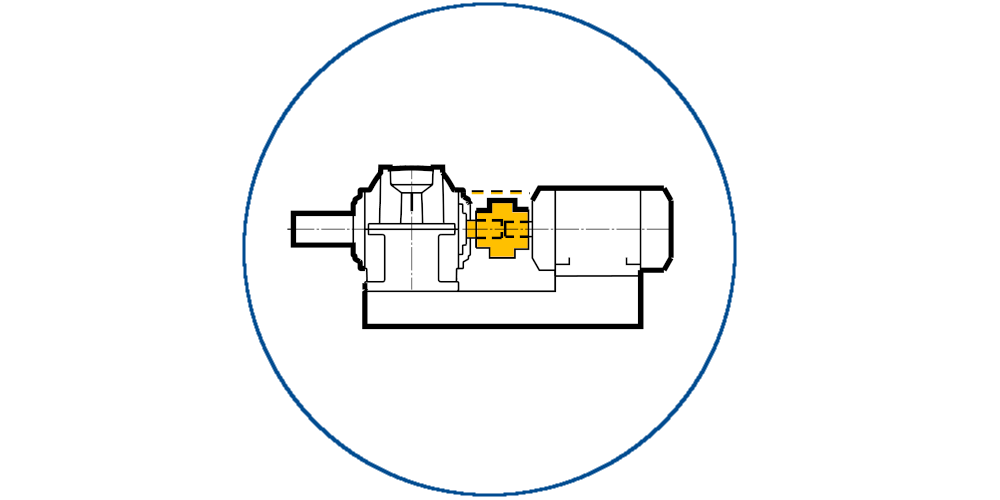

3 Motor Adapters

According to the motor requirements we can select from a wide range of motor adapters for both horizontal and vertical units according to various standards such as IEC and NEMA, making it possible to create flexible engineered solutions as a perfect fit to your needs.

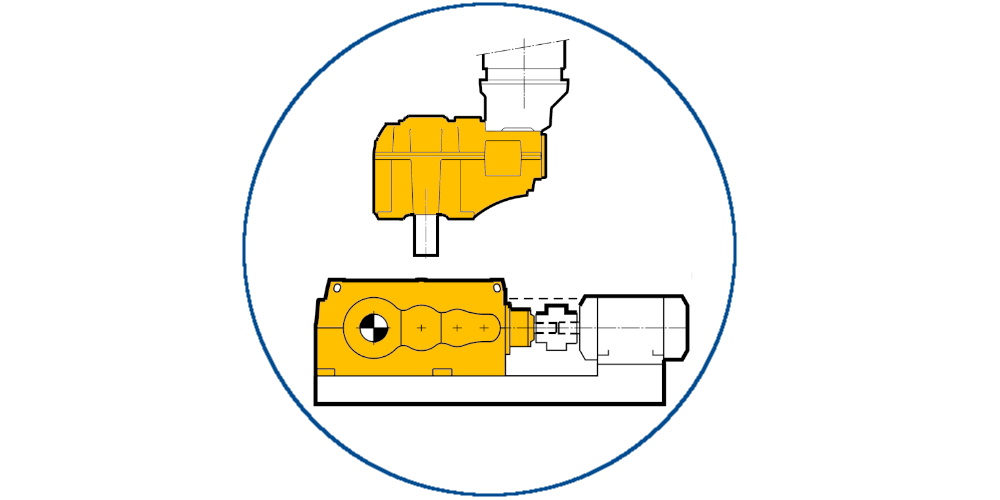

4 Supporting Structures

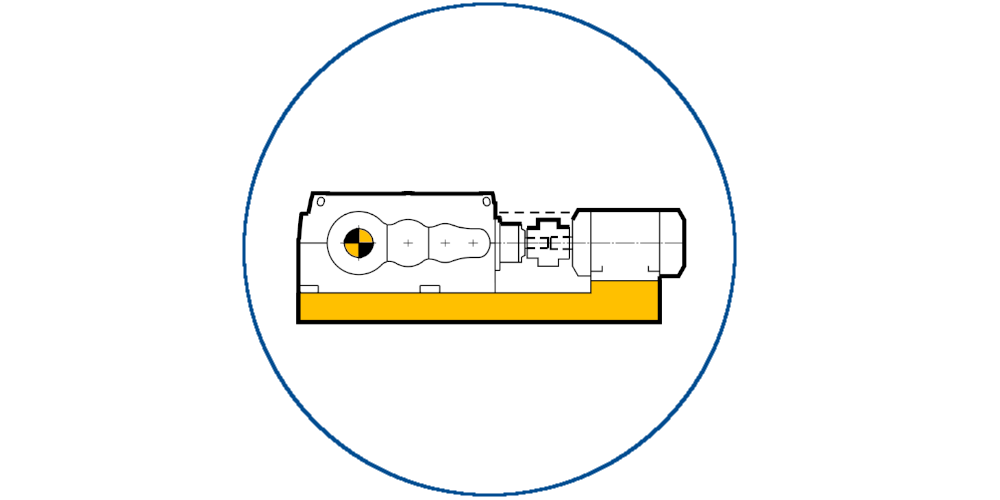

Swing base

In case of shaft mounted drives where the gear unit and the motor are mounted on a steel fabricated base frame, we are able to provide flexible engineering solutions in accordance with the customer specifications to ensure perfect alignment of the motor to the gearbox is maintained during operation. Our engineers utilise Finite Element Analysis (FEA) to ensure the base frame is designed in the most efficient way to provide maximum strength and stiffness of the drive package. The torque arm holds the drive package in position and prevents the drive package from rotating. All other forces are absorbed through the output shaft.

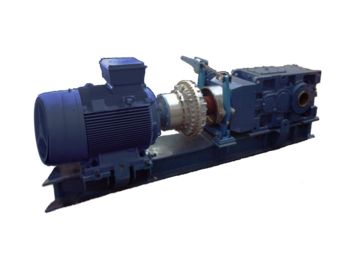

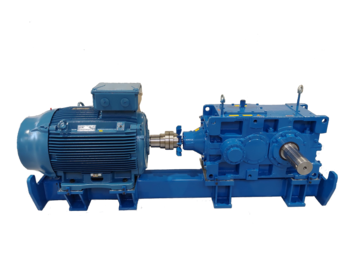

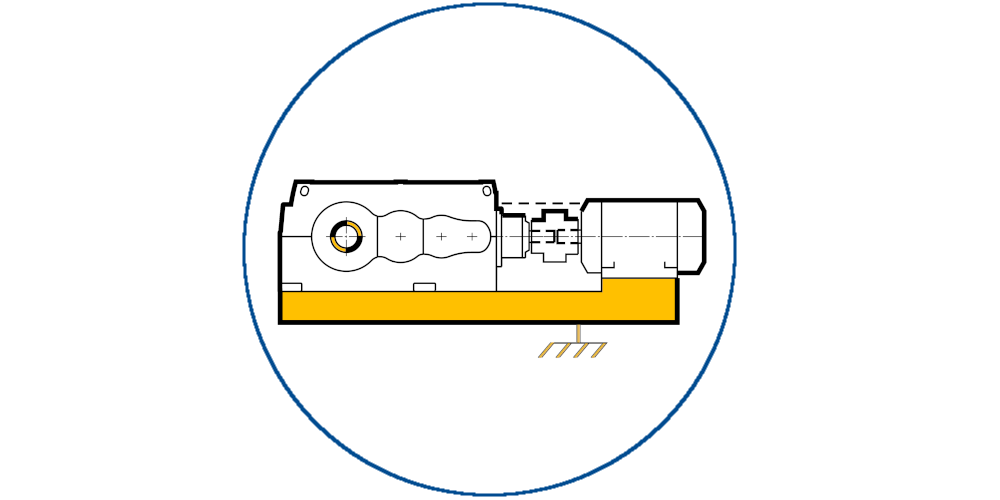

Common base

In case of foot mounted drives where the gear unit and the motor are mounted on a steel fabricated base frame designed order-specific in respect to the customer specifications to ensure a perfect alignment of the motor to the gearbox. The frame is rigid connected to the floor and designed to absorb external forces and torques of the machine and to deflect them to the supporting structure. Also mounting pads for couplings, protection guards and brakes or auxiliary drives (if required) will be included.

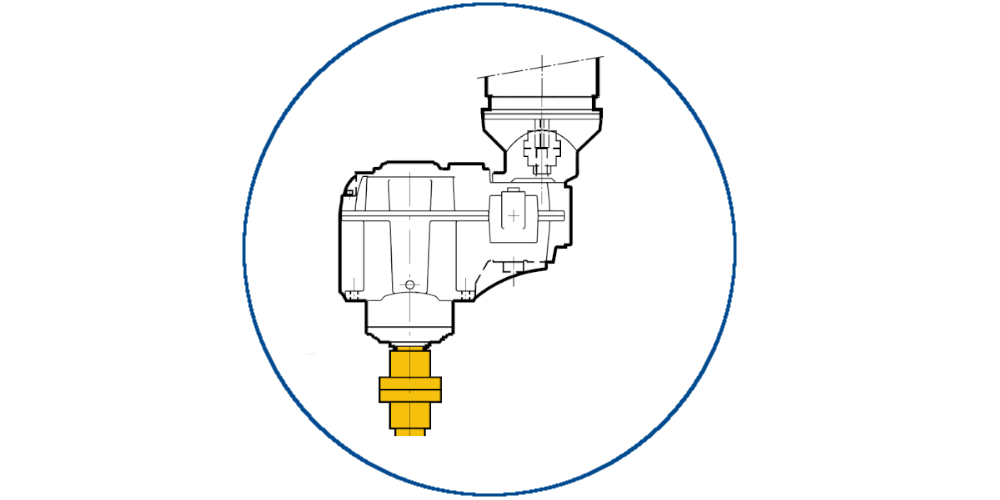

Motor base

In case of pulley drive, there is also the possibility to mount the motor to the gear unit . The motor can be installed on top of the gear unit , or for vertical gear units this can also be done at the side. The design typically provides enough clearance to still maintain access to the gearbox inspection cover and enough motor mount adjustment to allow for ease of installation of belts or chains.

Custom made

Manufacturing of various types of flanges or supporting structures special made to customer specifications.

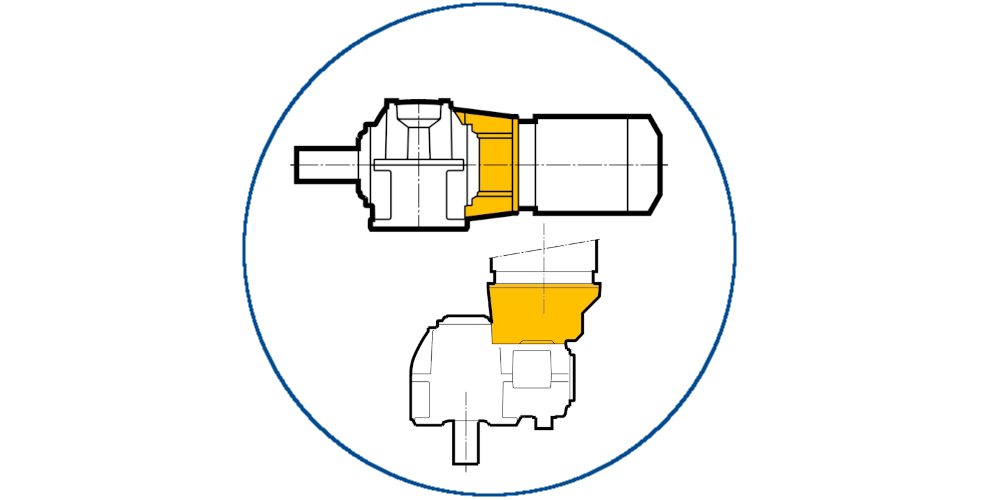

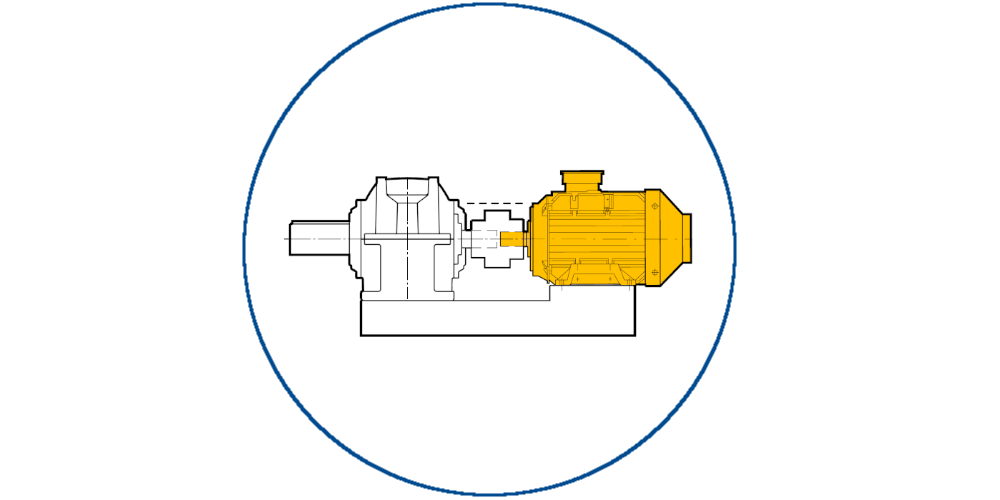

5 Motors

We complete your drive package solution equipped with an electrical motor perfect to your needs and according to the latest standards (e.g. IEC, NEMA) and efficiency classes. Various mounting types foot/flanged are possible based the motor adaptor or supporting structure. Optionally brake motors or ATEX certification can be supplied too.

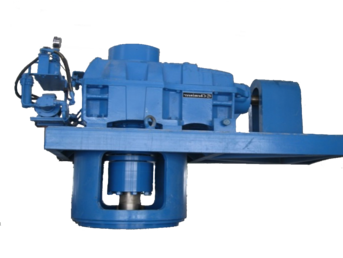

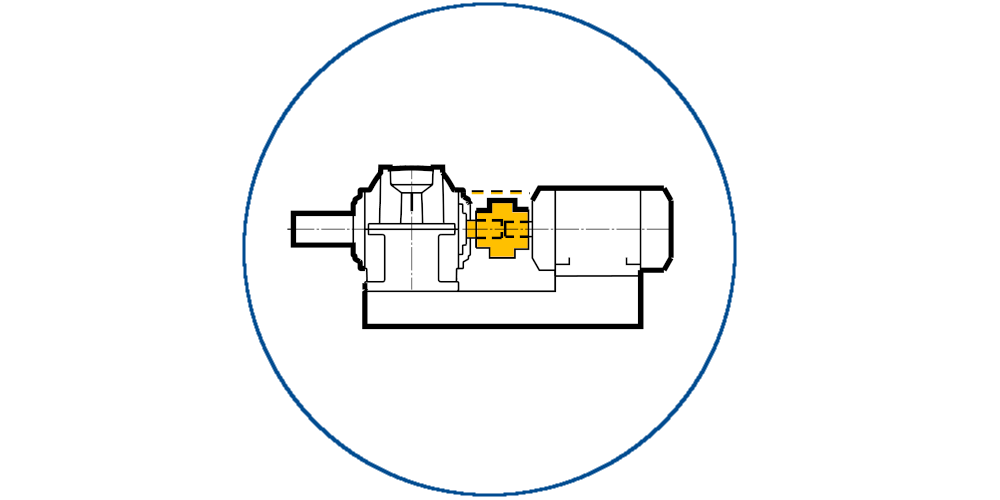

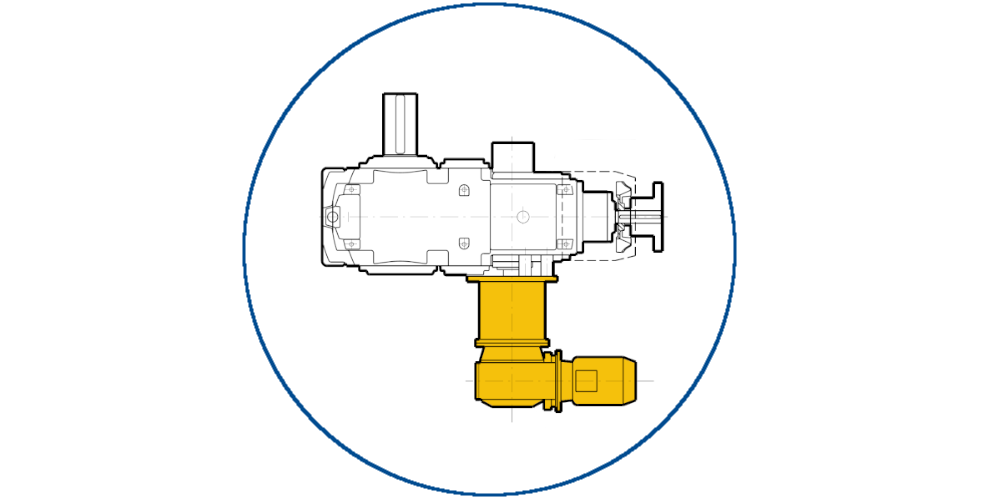

6 Auxiliary Drives

To keep the installation running at reduced speed in case of system failure, auxiliary ('inching') drives could be a beneficial solution. Typically found in people transport, bucket elevator, or toaster drive applications this is often a requirement. The auxiliary drive may include an in-line or right-angle geared motor connected to the main gear unit by chain, freewheel or clutch coupling. The auxiliary drive can also be equipped with an electric over speed control sensor that triggers the immediate stop of the main motor in case of mal-function-of the clutch or the freewheel.

7 Output Shaft

Couplings output shaft

Depending on customer requirements, various types of couplings are suitable for connecting the drive package to the customer's application shaft. In particular, these include pin, claw, gear and rigid flange couplings. Rigid flange couplings typically with keyway (for cooling technology applications), shrink fit (rigid fit) on keyless output shaft or with shrink disc (both conveyor). Gear couplings are often selected when there is limited space/high torque and high angular misalignment possible. Pin/claw coupling, due to their elastic properties, dampen motor impacts and vibrations towards the gear unit.

Protection guards

The shaft and coupling needs to operate at all times under safe conditions according to applicable standards. Typically design your Protection guards according to e.g. EC Machinery Directive.

Enhance Your Sumitomo Gearmotor

Combine your gearbox drive trains with our gearmotors

Interested in our drive package solutions?

Get in touch with us and we will provide you the best possible fit.