Strain Wave Gearbox

Strain Wave Gearboxes represent a specialized category of gear systems that leverage the mechanics of elasticity and harmonic distortion to transmit power with high precision.

This unique operation enables strain wave gearboxes to offer significant advantages in terms of high reduction ratios, compactness, and near-zero backlash, making them ideally suited for applications requiring precise control and reliability.

Strain Wave Gear Box Options From Sumitomo

Our Strain Wave gearbox, the E-Cyclo, features a highly compact design to achieve excellent torque density. The torsional stiffness is approximately twice that of the general strain wave gear competitor. This precision gearbox was created using a trochoid tooth design similar to our Cyclo® for zero backlash applications.

Torque

Nominal: Up to 67 N•m (6.8 kgf•m) / Acceleration: Up to 284 N•m (29.0 kgf•m)

Diameter

Up to 25.5 mm (Hollow Bore)

Ratio Range

29:1 to 283:1

Input Speed

Up to 8,500 RPM

Elastic Cyclo (ECY)

High Precision Shaft Gear with Output Flange & High Rigidity

Compact Zero-Backlash Gearbox blending traditional strain wave reduction and cycloidal engagement technology. The ECY precision gearboxes were created using a trochoid tooth design similar to our Cyclo® for zero-backlash applications.

The ECY features a highly compact design to achieve excellent torque density.

The torsional stiffness is approximately twice that of the general strain wave gear competitor. The ratcheting torque (safety in the event of an overload) is much higher due to our inclusion of the cycloidal tooth design, which is unique to the market.

More Information About Strain Wave Gearboxes

This blog explains the fundamental operation of a strain wave/harmonic-type gearbox, shedding light on its internal mechanics and the roles of its critical components.

Discover the key differences between Strain Wave and Cycloidal Gearboxes to select the perfect drive solution for your robotics application.

We offer a comprehensive lineup of high-quality motion control gearboxes.

Download our brochure to review our products.

Download our Zero Backlash Precision Drive catalog for all the technical specs you need to build the perfect drive for your operation.

The Gear Principle of a Strain Wave Drive

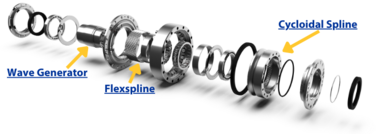

The gear principle of a strain wave gearbox revolves around utilizing the elasticity of materials to transmit torque and achieve a substantial reduction ratio within a compact and precise setup. This gear system is distinguished by three main components: the wave generator, the flexspline, and the circular spline, each playing a crucial role in its operation:

-

Wave Generator: The wave generator, a specially designed circular disk mounted with an elliptical bearing, is at the heart of the harmonic-type drive's gear principle. It is integral to initiating the gear's unique operational mechanics by being placed inside the flexspline.

-

Flex Spline: The flex spline is a flexible, thin-walled cylinder outfitted with external gear teeth on its wider end. Its construction from a pliable material enables it to conform to the shape imparted by the wave generator, transforming into an elliptical form that is essential for the gear principle to function.

-

Circular Spline: Acting as a static counterpoint to the flexspline, the circular spline is a rigid circular ring featuring internal gear teeth. It has a slightly higher tooth count than the flex spline, a difference that is pivotal to the gear principle's effectiveness.

Core Attributes of the Gear Principle:

| Compactness and High Reduction Ratios: | The strain wave gear principle enables the achievement of high reduction ratios (up to 1:320 in a single stage) in a small package, ideal for space-constrained applications requiring fine control. |

|---|---|

| Precision and Minimal Backlash: | The harmonic-type drive principle's design ensures very low backlash, facilitating high precision in tasks that demand exact positioning. |

| Robust Torque Delivery: | Despite their compact dimensions, strain wave drives are capable of transmitting considerable torque, making them suitable for power-dense applications where space is limited but high performance is necessary. |

Frequently Asked Questions (FAQs)

Here is a list of frequently asked questions (FAQs) about a Strain wave Drive and their answers.

What is a strain wave gearbox?

What is a strain wave gearbox?

A strain wave gear box is a type of gear system that produces high reduction ratios in a compact size. It uses the mechanics of a flexible element deforming to transmit motion and achieve high precision and torque.

How does a harmonic gear box work?

How does a harmonic gear box work?

A harmonic gear box works by using a circular spline, flexspline, and a wave generator. The wave generator deforms the flexspline into an elliptical shape, which then engages with the teeth of the circular spline at two points, providing a high reduction ratio through the difference in tooth count between the engaged elements.

What are the main components of a strain wave drive?

The main components are the circular spline (fixed outer ring), the flexspline (flexible inner ring with fewer teeth), and the wave generator (an elliptical disc that fits inside the flexspline).

What are the advantages of using harmonic/strain wave gear boxes?

Strain wave/harmonic gearboxes offer high precision, zero backlashes, high torque capacity, compact size, and lightweight. They are also known for their excellent positional accuracy and repeatability.

What applications are harmonic-type drives used in?

They are used in applications requiring high precision and reliability, such as robotics, aerospace, defense, medical equipment, and semiconductor manufacturing equipment.

How do you select a strain wave drive for a specific application?

Selection depends on factors like torque requirements, desired reduction ratio, space constraints, load capacity, and environmental conditions. It's essential to consult with manufacturers or experts to choose the appropriate model.

What are the different types of Strain Wave Gearboxes

- Circular Spline Gearboxes

- Cup-Type Gearboxes

- Flat Gearboxes

What is a Circular Spline?

The Circular Spline in Strain Wave Gearboxes are characterized by their robust design, which includes a circular spline with internal teeth that engage with the teeth of a flexspline. This design is suited for applications requiring high torque transmission and precision. Its structure allows for the efficient distribution of load, making it reliable for heavy-duty operations. This is different than the two other variations: Flat Harmonic and Cup.

What is a Cup-Type strain wave gearbox?

Cup-Types of Gearboxes stand out due to their compact and efficient design, where the flexspline takes the shape of a cup that encloses the wave generator. This configuration minimizes the gearbox's axial length, making it ideal for space-constrained applications. The cup-type design is particularly favored in robotics and aerospace applications, where size and weight are critical factors. This is different than the two other variations: Flat Harmonic and Circular Spline.

What is a Flat Strain Wave Gear Box?

Flat Strain Wave Gearboxes or harmonic gear boxes offer a solution for applications requiring a low-profile design. These gearboxes are distinguished by their flat shape, which results from a specially designed flexspline and wave generator. The flat gearbox is particularly useful in applications where the installation space is limited in height but not in diameter, offering high torque and precision in a slim package. This is different than the two other variations: Cup and Circular Spline

Why is there zero backlash in harmonic gearboxes?

Zero backlash is achieved because the flexspline's elastic deformation allows for continuous contact with the circular spline at the engagement points, ensuring no gap or play between the gear teeth. This characteristic is crucial for applications requiring high precision.

What is the difference between a harmonic gearbox and a traditional gearbox?

The main difference lies in the mechanism of motion transmission and design. They use a flexible element and achieve high reduction ratios in a very compact form factor with minimal to zero backlash, while traditional gearboxes use rigid gears and may not provide the same level of precision or compactness.

Can harmonic gear boxes/strain wave gear boxes be used in servo systems?

Yes, harmonic geardrives are ideal for servo systems due to their high precision, torque density, and minimal backlash, making them suitable for applications requiring accurate positioning and smooth motion control.

What are the limitations in terms of speed for strain-wave gearboxes?

What are the limitations in terms of speed for strain-wave gearboxes?

While offering high torque and precision, harmonic/strain wave gearboxes have limitations in maximum operating speed due to heat generation and the design of the flexspline. Operating beyond recommended speeds can reduce efficiency and lifespan.

Are these gearboxes suitable for robotics applications?

Yes, these drives are widely used in robotics due to their compact size, high torque-to-weight ratio, and precision. They are especially favored in joint actuation for robotic arms, humanoid robots, and precision grippers.

What is the strain wave gearing principle?

What is the strain wave gearing principle?

The strain wave gearing principle, also known as harmonic drive technology, uses a unique mechanism involving three main components:

- Wave Generator: An elliptical cam encased in a flexible bearing.

- Flexspline: A flexible, cup-shaped gear that deforms to match the shape of the wave generator.

- Circular Spline: A rigid, internal gear with teeth that mesh with the flexspline.

As the wave generator rotates, it flexes the flexspline, causing the teeth of the flexspline to engage with the circular spline at specific points. The gradual and selective engagement results in precise motion control, high reduction ratios, and zero backlash performance.

What is the difference between strain wave gearbox and cycloidal drive?

What is the difference between strain wave gearbox and cycloidal drive?

- Design:

- Strain wave drives use flexible components to achieve deformation-based meshing for motion transfer.

- Cycloidal drives use rotating discs (cycloidal gears) and pins to create smooth, rolling motion.

- Backlash:

- Strain wave drives typically offer zero backlash for ultra-precise applications.

- Cycloidal drives have minimal backlash but not completely zero.

- Reduction Ratios:

- Strain wave gearboxes can achieve extremely high reduction ratios in compact spaces.

- Cycloidal drives can also achieve high ratios but are typically bulkier for equivalent ratios.

- Applications:

- Strain wave drives are favored in robotics and motion control for accuracy.

- Cycloidal drives excel in heavy-load industrial applications due to their high shock load capacity.

What is the reduction ratio of strain wave gear?

What is the reduction ratio of strain wave gear?

The reduction ratio of a strain wave gear is determined by the number of teeth difference between the flexspline and the circular spline. Typical reduction ratios range from 30:1 to 320:1, with some designs capable of even higher ratios depending on the specific configuration. This wide range makes strain wave drives highly versatile for applications requiring both fine precision and substantial torque multiplication.

How is the price of a strain wave gear determined?

How is the price of a strain wave gear determined?

The price of a strain wave gear depends on several factors, including the size, reduction ratio, torque capacity, and any customizations for specific applications. High-precision models used in robotics or aerospace may cost more due to their specialized performance and zero-backlash design. Additionally, brands, material quality, and additional features (like integrated encoders or seals) can influence the overall cost. For a detailed quote, it’s best to consult with our team here

Ready to Start The Process to Order Your Own E-Cyclo?

Start the process today! Send us a message, and we'll contact you as soon as we can. You can also email us at [email protected].