Cyclosmart Early Detection

Why do we need Predictive Maintenance? What can IIoT do for my operation? The answer? Prevent costly downtime. Maintenance teams can’t be everywhere all at once in today’s factory. Too many pieces of equipment, and not enough hours in the day. Even in some of the best maintained systems, things will get missed. IIoT can help maintenance personal be in more than one place at time. 24/7 live monitoring ensures that no issues go missed. For example, in an Automotive assembly plant, there are so many different systems working in multiple sections of the facility. Paint, Stamping, Assembly, etc., all these departments are critical to keeping production going.

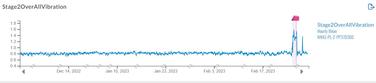

We recently received a success story from an Automotive assembly plant that uses the CycloSMART. Using a CycloSMART Monitoring system, maintenance staff were alerted to a rise in vibration on a specific location and piece of equipment. Upon further inspection, they were able to see that a weld on a section of conveyor frame had fatigued and had failed. They were able to take quick action, make a repair, and keep the operation going. Preventing thousands of dollars of downtime per hour. CycloSMART, an IIoT solution, can help keep your operating running, and catch things that your maintenance staff could potentially overlook making their job easier.