Gearmotors

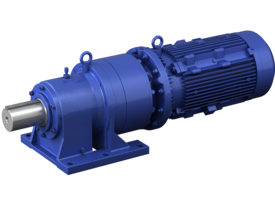

Gearmotors are an essential tool for many drive systems. With unique designs and configurations available, gear motors can be used to increase torque, reduce speed, reverse direction, or change the push or pull of a driveshaft. For over 80 years, Sumitomo Drive Technologies has been providing world-class gear motors, gearboxes, and speed reducers, featuring industry-leading technology with fully integrated premium efficient motors. Our impactful power transmission units come in various shaft configurations such as right angle, concentric and parallel shaft.

Do you want something quick and with uncompromised power? A Sumitomo gear motor is the way to go.

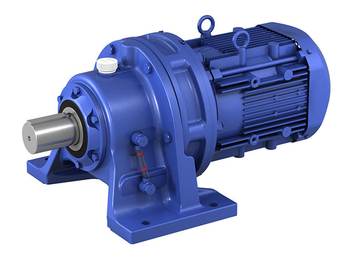

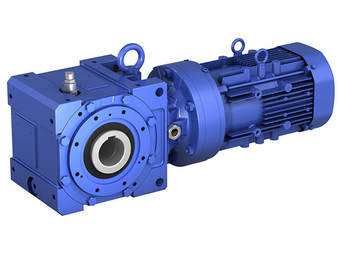

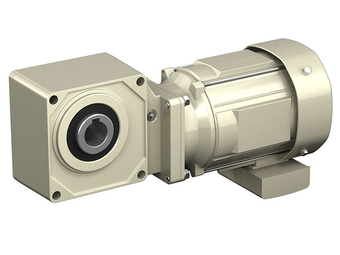

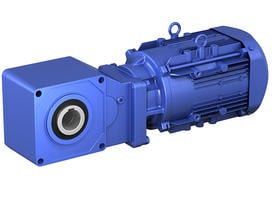

Our Best Selling Gear Motors

Why Rely on Sumitomo?

To power your operation, Sumitomo provides a comprehensive lineup of products with the gear ratios, torque, and horsepower you need. All of our premier products are available from our manufacturing facilities in Virginia, Illinois and Texas. Our engineers will be able to craft a custom solution to match your design specifications if none of our stock products fit your needs.

Sumitomo products go beyond just the nameplate ratings. With us, you get peace of mind. It doesn't matter if you are designing a new machine or simply upgrading an existing one, you can depend on our team to provide you with a power transmission solution that will be efficient, convenient, and trouble-free for many years to come.

Our high-performance units are designed for equipment where downtime is not an option.

For repairs, our Aftermarket team is here to help. Gearbox problems are our expertise. Our technicians have extensive industry experience. For maximum gearbox life, we offer both standard and customized services.

The Ultimate Guide to Gearmotors: Everything You Need to Know

8 Types of Gearboxes and Their Applications

This blog post covers cycloidal, helical, spiral bevel, worm, planetary gear units, and more.

Why Sumitomo Products are the Best Option to Increase the Life of Your Application

Trying to decide between Sumitomo gear drives and competitors. Here's what makes our industrial gearboxes stand out.

Gear Drive Selection Guide: Tips for Finding the Perfect Gear Box to Power Your Operation.

Expert tips and strategies for choosing the best power transmission option for your industrial application.

Upgrading to High-Efficiency Motors: How to Save Energy and Money

Discover how upgrading to a high-efficiency IE5 motor can save energy and money for your business.

⚙️ What is the Difference Between an AC Gear Motor and DC Gearmotors?

Confused between AC gear motors and DC gearmotors? When it comes to power transmission, these units play a crucial role in many applications, from manufacturing to robotics. However, with so many options available, choosing the right type for your operation can be difficult.

Two of the most common types of gear units are DC and AC gearmotors, each with its own advantages and disadvantages. In this blog, we'll provide a comprehensive guide to the differences between these electric motors, including their key features, common applications, and performance characteristics. Read more here.

⚙️ What is the Difference Between Concentric, Right Angle and Parallel Shaft Gearmotors?

A gearbox's shaft arrangement refers to how the gearbox's input and output shafts are arranged in relation to each other. The three primary shaft arrangements are concentric, parallel shaft, and right angle gear drive. Each of these designs has its unique advantages and disadvantages, and selecting the right one requires careful consideration of what your application requires.

In this article, we'll provide an in-depth exploration of the different gearbox shaft arrangements and how they impact gearbox performance. We'll examine each type's unique characteristics and discuss each's benefits and drawbacks. Read more.

⚙️ Five Sumitomo Gearmotors to Boost Your Industrial Efficiency

Sumitomo gear motors offer exceptional reliability, efficiency, and precision in a wide range of industrial applications. From the high-performance Cyclo BBB4 drive to the versatile Helical Buddybox, Sumitomo products are designed to provide superior performance and durability.

Are you looking for a reliable and efficient way to transmit power to your industrial application? Look no further than Sumitomo! In this blog post, we highlight the top 5 Sumitomo gearmotors to consider for your machinery. Read more

⚙️ Important Factors to Consider When Sizing and Selecting a Gear Motor

When it comes to selecting the right gearmotor to transfer power to your operation, there are several critical factors to consider. From load requirements and duty cycle to the output speed to motor overload capacity and gear ratio, each factor plays a significant role in ensuring optimal performance and reliability. In this section, we will dive into the key factors you need to consider when sizing and selecting a gear unit to ensure it can handle the load, improve efficiency, and withstand environmental factors. Read more

⚙️ Common Gear Drive Selection Mistakes to Avoid

Selecting the wrong gear motor can seriously affect your application, from premature failure to decreased efficiency and increased operating costs. Unfortunately, several common mistakes can occur when selecting a gear motor. In this blog, we will explore some of the most common mistakes to avoid, including overlooking environmental factors, ignoring duty cycle, oversizing the motor, and not considering motor overload capacity.

By understanding these mistakes, you can make informed decisions when selecting a product and ensure optimal performance and reliability. Read more

⚙️ Gear Box Sizing and Selection Best Practices

Proper gearmotor sizing and selection are critical for ensuring optimal performance and reliability in your application. Choosing the wrong product can lead to many operational problems, increased repairs and maintenance, incorrect output speeds and unscheduled downtime. To avoid these issues, it's essential to follow best practices when sizing and selecting a gear drive for your application. Read more

⚙️ Considerations for Selecting Conveyor Power Transmission Equiptment

When choosing gear motors for conveyor systems, consider key factors such as shock load, speed, torque & maintenance requirements, energy efficiency, and more. Read More

Power Transmission Fundamentals & Gear Ratios

This pre-recorded webinar reviews Power Transmission Fundamentals such as HP Torque, Gearing and Gear Manufacturing, Gear Ratio and its Impact on Power Ratings, Service Classes, Application Service Factors, Ambient Effects, and more gearmotor must-knows.

How to Properly Select a Gearbox for Any Application

Explore the proper application Information needed to help you select the perfect gearbox or reducer. Review with our gearbox expert, Adam Soder, step-by-step illustrations of selecting a gearbox for any application.

Frequently Asked Questions

There are many types of gearboxes to choose from when you're in the market to repair or replace an existing unit or install a new gear motor. Sumitomo has option that can fit into your application with ease. To help save you time and hours of research, we've compiled a list of Frequently Asked Questions.

What is a gearmotor?

What is a gearmotor?

Gearmotors are made up of a motor, gear, and bearings enclosed in a housing. They are frequently used in applications that require a high amount of force (torque) at low speeds. A gearmotor powered by AC current performs many tasks related to high power, such as lifting, jacking, and robotics. Brackets, covers, and extension cables are used to mount, protect, and power gearmotors.

How does a gearmotor work?

How does a gearmotor work?

The primary function within a gearmotor is handled by the gear unit and its stages. These features transfer the force of the motor from its input to its output. As a result, the gear motor functions as a speed and torque converter.

Power transmission products are for speed control! They typically slow down motor rotational speeds while transmitting greater torques than an electric motor can provide by itself in most applications. Considering this, the design of the product will determine whether a gearmotor is suitable for light or medium loads and for short or long power-applied hours.

Reduction ratios or gear ratios refer to how the power transmission device steps down or steps up the motor's incoming speed (known as the input speed). Another measure of a gear motor's performance is the maximum torque it has on the output side. Torque is measured in Newton meters (Nm), and it refers to the force of the gear motor and the load that it can move with that force.

What types of gearmotors are available?

What types of gearmotors are available?

The primary factor in determining the type of gearmotor is the shaft configuration of the gear unit. We offer three different designs such as right-angle gearmotors, parallel-shaft gearmotors, and concentric units.

Where are gearmotors used?

Where are gearmotors used?

The easy answer is--EVERYWHERE! Sumitomo units can be found in the parcel handling industry, mining industry, food & beverage industry and more. Anything that needs to be moved-- 9/10 is powered by some type of gearmotor.

What are the standard Cyclo input speeds?

What are the standard Cyclo input speeds?

In general terms, the speeds are 1750 and 1165 RPM. The selection tables in our catalog are based on 1750, 1165, 870, 580, and 50 RPM. When non-standard input speeds are used, the kilowatt (or horsepower) and torque ratings also vary.

My application has severe operating conditions. Can a Sumitomo gearmotor handle that?

My application has severe operating conditions. Can a Sumitomo gearmotor handle that?

The standard ratings for Cyclo® BBB4 are based on 10-hour daily service under conditions of uniform loads (equivalent to AGMA service factor 1.0). By following the product selection process outlined in our catalog, you will determine and apply the Service Factors to compensate for the severe operating conditions.

What information do I need to select the right gearmotor?

What information do I need to select the right gearmotor?

To select the proper gearmotor for your application, you need to know:

- Application: type of driven machine

- Hours of operation per day

- Motor horsepower (HP) and speed (RPM)

- Mounting position

- Ambient environment, temperature and humidity

- Special environment factors or operational requirements.

What are the benefits of using a gearmotor?

The benefits of using a gearmotor include:

- Increased torque output

- Improved speed control and precision

- Reduced noise and vibration

- Smaller footprint compared to separate motor and gearbox

- Simplified installation and maintenance

- Greater efficiency in power transmission

What are the different types of gearmotors?

There are several types of gearmotors available, including:

- Helical gearmotors

- Planetary gearmotors

- Worm gearmotors

- Bevel gearmotors

- Cycloidal gearmotors

How do I choose the right gearmotor for my application?

To choose the right gearmotor for your application, you should consider factors such as the required torque and speed, environmental conditions, space limitations, and efficiency requirements. It's also important to consider the specific type of gearmotor that would be best suited for your application.

What is the difference between a gearmotor and a gearbox?

The main difference between a gearmotor and a gearbox is that a gearmotor is a combination of a motor and a gearbox, whereas a gearbox is a standalone mechanical device used to transmit power between a motor and a driven load.

What are the environmental considerations when using gearmotors?

Environmental considerations when using a gear motor include factors such as temperature, humidity, and exposure to corrosive substances. Proper sealing and ventilation can help protect the gear motor from these conditions.

What is the lifespan of a gearmotor?

The lifespan of a gearmotor depends on several factors, such as the type and quality of the motor and gearbox components, the operating conditions, and the maintenance schedule. With proper care and maintenance, gearmotors can last for many years.

What are the safety precautions to take when working with gear motors?

Safety precautions when working with gearmotors include following proper lockout/tagout procedures, wearing appropriate personal protective equipment, and ensuring that the motor is properly grounded and secured before starting any maintenance or repair work.

How do I select a supplier or manufacturer for gear motors?

When selecting a gearmotor supplier or manufacturer, it's important to consider factors such as the company's reputation, product quality and reliability, customer service and support, and pricing.

Can I add an Inverter product to Sumitomo gear motors?

Yes, Sumitomo now offers Invertek Variable Frequency Drives (VFDs). The Invertek Optidrive inverters provide advanced motor control with ease of setup and operation. They are also capable of operating in some of the harshest environments thanks to the IP66 / NEMA 4X-rated enclosures available across the E3 and P2 ranges. Learn more about them here.

How can I search Sumitomo product documentation using my mobile device?

Every Sumitomo product comes with a scannable QR Code. Point your device at the QR Code, and it will take you to this page. You can add this page to your favorites folder or bookmark it for easy access to our product literature.

What is a DC Gear Motor?

A DC gear motor is commonly used for applications requiring precise speed control or frequent starting and stopping because they use direct current (DC). Other applications include automotive, robotics, and medical equipment. There are several advantages to using a DC gear motor over an AC gear motor, including:

-

High torque and power output

-

Precise speed control

-

Good starting and stopping capabilities

-

Compact size and lightweight design

The disadvantages of a DC gear motor include higher costs, more complex control systems, and higher maintenance requirements.

What is an AC Gear Motor?

An AC gear motor is an electrical device that uses alternating current (AC) to drive them. The drive is often used in conveyor systems, pumps, and compressors, all of which require constant speed. Compared to other types of gearmotors, a AC gear motor have the following advantages:

-

High reliability and durability

-

Low maintenance requirements

-

Smooth and quiet operation

-

Energy efficiency

While an AC gear motor has some advantages, it also has some disadvantages, such as its limited speed control and tendency to overheat at high loads. It is essential to take these factors into account when choosing an AC gear motor versus a DC gear motor.

What AC gear motor options does Sumitomo have?

In 2019, Sumitomo Drive Technologies acquired the Lafert Group, a European leader in the design and production of electric motors and drivers customized for industrial use. Lafert offers High Performance (HP), a new generation of PM (Permanent Magnet) Synchronous Motors, which achieve IE5 Super Premium Efficiency level and are very compact.

It combines the electrical design of Brushless Servomotors with the mechanical design of AC Induction Motors. Thus, the compact motor is primarily designed for HVAC applications such as fans, compressors, and blowers, where there is an emphasis on reducing the motor's weight and size.

How do I select the correct size for my gear motor?

In order to size the right gearmotor for your application, you need to consider several critical factors. Optimal performance and reliability are dependent on many factors, from load requirements and duty cycle to motor overload capacity and gear ratio. During this section, we will examine the factors you must consider when selecting and sizing gearmotors to ensure they can handle loads, improve efficiency, and withstand environmental conditions. Making the right choice for your specific needs requires taking these factors into account.

With Sumitomo, The Options are Endless and Obtaining a Quote is Easy!

To accompany your next Sumitomo gearbox, we offer Inverters (Variable Frequency Drives), speed reducers, and options to lower your overall maintenance requirements and increase efficiency. To receive a quote, please complete our short form with your name, email address, and a few more details, or reach out to our team of District Sales Managers.