Large Industrial Gearboxes

Sumitomo's Large Industrial Gearboxes feature a easily accessorized and customizable standard line of catalogued speed reducers for your demanding heavy-industrial applications. We're the gearbox manufacturer you need.

The widest range of standard cataloged large industrial gearboxes on the market.

Powered by a robust, proven design, Paramax Large Industrial Gearboxes & Speed Reducers are rugged, flexible, and economical to operate. A wide range of options is available at a reasonable cost, allowing quick shipping.

With Hansen Large Industrial Gearboxes & Speed Reducers, you can find the perfect solution for even your most demanding applications. The Hansen vertical gearbox offers the best features required for heavy-duty and long-running applications.

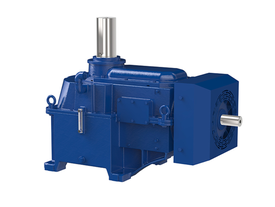

Paramax Industrial Gearbox Series

Paramax® parallel and right-angle drives are some of the largest and most durable power transmission systems operating in the world. The series features double, triple, and quadruple reduction gearboxes, global standardization, availability, and support from our worldwide facilities.

Typical optional accessories: Backstops, Motor Mount Options, Seal Upgrades, Heating & Cooling, and Lubrication Solutions, Paint Upgrades, Storage and Packaging Options, and Complete Drive Package Solutions.

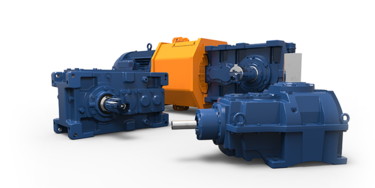

Hansen Industrial Gearboxes

Hansen industrial gearboxes are market-leading in quality, technology and integrated features and benefits demanded by users. Hansen industrial gearboxes excel in reliability and durability. The rugged housing, along with our commitment to innovating state-of-the-art technology, provides remarkable power and performance.

Specialty Speed Reducers

For non-standard gearing and custom ratios, we offer special customized units to fit in any application. From custom paint to intricate gearbox lubrication systems, our team of engineers will make sure all of your custom gearbox needs are met.

Retro-Fit and Drop-In Gearboxes & Gear Reducers

Whatever your requirements, we have a solution for you. Sumitomo Drive Technologies offers customized gearbox bases that allow our units to match the footprint of an array of existing applications and drop-in a unit to upgrade, replace and remove competitor gear boxes. With a wide range of options, our engineers can replace your unit with minimum impact on your application while delivering a premier product with performance and reliability.

Retrofitted Industrial Gearbox Replacement

With a custom transition base, the new low-speed shaft will be positioned exactly where the original low-speed shaft was. Compared to a standard gearbox, retrofitting with our large gearboxes provides maximum cost savings with minimal on-site modifications to your application.

This option typically requires just relocating the motor mount. In order to minimize the impact of relocating the motor mount, we offer motor mounting options, such as flanged motor adapters for c-face and d-flange motors.

Other options might include low-speed shafts with specific diameters or lengths and motor lanterns. In the diagram, the red circles indicate the existing bolt pattern of a customer's large gearboxes. Transition bases are made to match machine shaft height, ensuring that the low-speed shaft is aligned with the machine shaft.

Drop-In Industrial Gearbox Replacements

Because downtime is such an important factor for your business, let us install a custom drop-in unit. Installation-ready units are designed to seamlessly integrate into existing applications. We understand that on-site modifications or reengineering your system isn't always an option.

These stress-free units can have your application back up and running in no time. Custom gearing and shafting, fabricated steel housings, and more are all available. Same footprint, same shaft positions; it will literally drop into place.

Why Choose Sumitomo as Your High-Quality Large Industrial Gearbox Supplier?

The Sumitomo Manufacturing Standard

We ask the right questions to ensure you have the correct large industrial gearbox for your specific application. Customer experience is our top priority, and we want to ensure that our customers can get the modifications or custom options they desire. Our Paramax® and Hansen brands offer the widest range of large industrial gearboxes on the market. Historically, we have supplied products that have outperformed our competition in the toughest of industries, such as forestry, steel, and mining, and application like bulk material conveying, mixers, crushers, kilns and cranes. With a reduced average lead time, sizeable domestic inventory, and a staff of specialized engineers and manufacturers, customers are able to select from a wide range of products and options to solve their toughest problems.

The Right Gearbox or Gear Reducer for the Right Job

Standard large industrial gearboxes are pre-engineered and manufactured to be assembled from our inventory. Local engineering, manufacturing, and assembly allow us to customize these products to meet your needs. Our large gearboxes also have various upgrades and performance monitoring products to keep each gearbox in action. By following our preventative maintenance procedures, you ensure your gearbox lives a long life. If your gearbox has an issue, our experienced network of aftermarket experts is always available. Plus, with one of the longest warranties in the gearbox industry, your major operation is well protected.

If you ever have any questions regarding ordering our large industrial gear drives, CAD drawings, quotes, and more--please contact us.

Where Are Our Large Industrial Gear Boxes Manufactured?

Verona Gearbox Manufacturing Facility

Our industrial gearbox facility is tucked along the industrial corridor of I-81 in the picturesque Shenandoah Valley of Virginia. This purpose-built facility was designed to efficiently handle the inventory, machining, assembly, quality control, and testing for our entire line of industrial gearboxes in the United States.

Purpose-Built Facility

Optimized to build over 100 large industrial gearboxes a month. There’s little we can’t handle.

On-Site Machining Capabilities

With a full-service machine shop at our disposal, we keep costs and lead times down.

Dedicated Distribution Center

With centralized inventory to support the Western Hemisphere, we’ve got you covered.

Rigorous Standards

ISO 9001 certified. Member of AGMA, PTDA, CSA, EASA, CTI, & CEMA. We don’t compromise. Consult us to meet various ‘Made-in-America’ requirements.

Frequently Asked Questions (FAQs)

What is a large industrial gearbox, and how does it impact speed and torque?

What is a large industrial gearbox, and how does it impact speed and torque?

A large industrial gearbox is a mechanical system that adjusts speed and increases torque to enhance equipment performance. It ensures that applications requiring high torque output operate efficiently while maintaining optimal speed control.

How do large industrial gearboxes improve efficiency in heavy-duty equipment?

How do large industrial gearboxes improve efficiency in heavy-duty equipment?

Large industrial gearboxes optimize efficiency by reducing energy loss during torque transmission. By maintaining stable speed and distributing power effectively, they enhance the longevity and reliability of equipment in demanding applications.

What types of applications require large industrial gearboxes?

What types of applications require large industrial gearboxes?

Industries such as mining, cement, power generation, and manufacturing use large industrial gearboxes to control speed and manage torque in heavy machinery. These gearboxes are essential in applications requiring precision, durability, and high efficiency.

How do I choose the right large industrial gear box for my equipment?

How do I choose the right large industrial gear box for my equipment?

How does a gear box affect speed control in industrial applications?

How does a gear box affect speed control in industrial applications?

A large industrial gear box regulates speed by adjusting the input from the motor to match the required output for the equipment. This precise speed control helps maintain consistent efficiency and prevents unnecessary wear on machinery.

What are the maintenance requirements for large industrial gear boxes?

What are the maintenance requirements for large industrial gearboxes?

Routine maintenance for large industrial gearboxes includes monitoring lubrication, inspecting gears for wear, and checking speed and torque consistency. Proper maintenance enhances efficiency and extends the lifespan of the gearbox and connected equipment.

What signs indicate that an industrial gearbox needs replacement or an upgrade?

What signs indicate that an industrial gear box needs replacement or an upgrade?

Reduced efficiency, overheating, irregular speed variations, and insufficient torque output are common indicators that a large industrial gearbox may need an upgrade. Replacing outdated gearboxes ensures optimal equipment performance and prevents downtime.

Can large industrial gearboxes be customized for specific applications?

Can large industrial gearboxes be customized for specific applications?

Yes! Large industrial gearboxes can be customized to match specific speed, torque, and load requirements. A tailored gearbox solution ensures that your equipment operates with maximum efficiency in demanding applications.

What factors affect the efficiency of a large industrial gearbox?

What factors affect the efficiency of a large industrial gearbox?

The efficiency of a large industrial gearbox depends on proper lubrication, load capacity, operating speed, and torque distribution. High-quality materials and precision engineering also contribute to better overall efficiency in heavy-duty applications.

How do I get a quote for a large industrial gearbox for my equipment?

How do I get a quote for a large industrial gearbox for my equipment?

You can request a quote for a large industrial gearbox by providing details about your application, including required torque, speed, and equipment specifications. Our team will help you select the most efficient gearbox solution for your needs.

With Sumitomo, The Options are Endless and Obtaining a Quote is Easy!

To accompany your next Sumitomo gearbox, we offer Inverters (Variable Frequency Drives), speed reducers, and options to lower your overall maintenance requirements and increase efficiency. To receive a quote, please complete our short form with your name, email address, and a few more details, or reach out to our team of District Sales Managers.