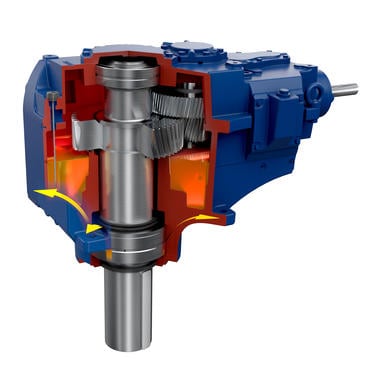

Hansen P4 Multistage - Vertical

Designed specifically for vertical applications

- Specific vertical housing - available in 20 sizes from 3 to 1100 kNm output torque.

- Increased bearing span for robustness against high overhung loads.

- Mounting feet symmetric around low speed shaft to evenly distribute loads.

- Service friendly with split housing and maintenance-free sealing system.

- Powerful Hansen P4 gear geometry for low noise and vibration levels.

- Designed for heavy-duty applications: Cooling towers, Mixers, Toasters, Pulpers and more.

| Number of Sizes | 20 |

| Housing type | Specific housings for vertical applications (split-plane) |

| Gears | Helical and Bevel helical (in accordance with AGMA) |

| Stages | 2, 3 or 4 stage |

| Reduction Ratios | 3.55:1 to 630:1 and special ratio's upon request |

| Nominal output torque | Up to 9.7M lb-in (1100 kNm) |

| Input speed | up to 1800 rpm |

| Shaft type | Solid or hollow low speed shaft |

| Lubrication | Pump lubrication |

Key Product Facts

Advantages of Hansen P4 Vertical Series

Extreme High Overhung Loads

- Rigid dedicated Hansen P4 housing design to ensure smooth transition of high forces from the centre bore to the mounting feet, which are positioned concentric to the low speed shaft.

- Possibility for extended bearing housing integrated in the housing casting and a wide range of robust bearing arrangements provides extremely high thrust load and bending moment capacity.

Oil-tight drywell

The standard integrated drywell prevents oil from leaking along the low speed shaft at any circumstances.

Document

Download PDF files for the latest catalogs, brochures, and data sheets.

Do you have questions about the Hansen P4 Multistage Unit?

Below are some of our most commonly asked questions, or you can view our Support area under Knowledge for more frequently asked questions and answers.

I don’t like the turnbuckle torque arms and sometimes have reversing applications they don’t work well for, do you have another option?

Yes, we have 6 different torque arm options to make your installation easy.

What if I need to change the backstop rotation?

No problem, your Sumitomo rep can assist with that, we can instruct you how, or you can send it to us to do.

Can I adjust the speed with a direct drive like I can with a belt drive?

Not by changing a sheave size since that component is eliminated, but there are things to consider…

- How often are you really changing the speed?

- The flexibility of changing a sheave size also puts your system at risk. Are you overspeeding beyond the reducer's capabilities? Are you slowing down too much and causing the backstop spragues to drag and wear?

If you are utilizing a VFD, that can control your speed.

- If you find out you truly need to change your speed, our BBB is the only direct drive on the market that has a Cyclo cartridge that could be changed to change your overall speed eliminating the need for a whole new reducer. Work with your Sumitomo rep to consider this.

I don’t have a very long shaft, can I still replace a belt drive with a direct drive?

Yes, if our standard Taper Grip Bushing requires more shaft than you have, we have a new Taper Grip Bushing option that needs an average of ½ the shaft length. When we size up the reducer you need, we can tell you how much shaft length you need for both options.

What should be some features or upgrades I should consider for the Aggregate, Sand and Cement industries?

Taconite Seals, Severe Duty or Desiccant Breather

What are backstops?

Backstops are safety devices and have to be inspected at regular time intervals. The periodical inspection is to be carried out by authorized personnel. The frequency of the inspection depends on the type of application. Please refer to the P4 service manual for recommended inspection intervals

What type of lubrication method does the P4 use?

Hansen P4 units use one of the following systems:

- Splash Lubrication (standard with horizontal shaft gear units for speeds between 750 and 1800RPM at the high speed shaft. Gears and output shaft bearings are lubricated by immersion in the oil bath. Oil splash from gears fill the oil pockets in the housing, assuring gravity circulation lubrication of the bearings via channels in the housing and covers.)

- Force Feed Lubrication (all rotating elements above oil bath level are lubricated by a gear pump forcing the oil through pressure lines. Forced feed lubrication is available as circulation lubrication or pressure lubrication.

How often do I change the oil?

The first oil change should be carried out preferably after 100 hours and not more than 800 hours of operation. The removed oil may be used again after filtering. Filter the oil volume at least 10 times using a 10mm filter or smaller. Subsequently the oil should be renewed after 4000 to 8000 hours or maximum of 18 months of operation depending on working conditions. Please refer to service manual for detailed oil change instructions.

What type of lubrication should be used?

Mineral oils containing EP additives, which increase oil film load capacity should be used. Refer to the P4 service manual for recommended oil types.

Related Hansen Industrial Gearboxes products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.