Get Your Brew on the Move with Right Angle Reducers

Hopefully, you already have a few green items to wear, so you don't get pinched on St. Patrick's Day. With the holiday fast approaching, many are preparing to celebrate to the fullest. More than 33 million party goers around the globe participate in St. Patrick's Day festivities every year. Consumers will guzzle (or sip) more than 15 million pints of Guinness and other beers on March 17th.

In the United States, the beer industry has grown exponentially over the last decade. From craft breweries to cultural favorites--beer is a fan fave. According to the National Beer Wholesalers Association, in 2018, beer distributors shipped 202.2 million barrels of beer–-equivalent to more than 2.8 billion cases.

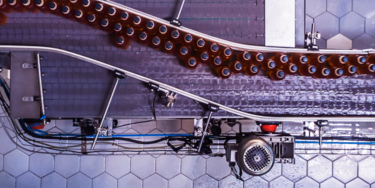

With so much demand for America's favorite fermented beverage, breweries have had to scale-up operations, producing more beer than ever before. Getting this beer bottled or canned, and out to local markets requires one application we are all familiar with, conveyors. Brewery conveyors are used for bottling, canning, or simply to move cans or bottles through labeling and packaging machinery. These applications operate for long hours and move a high volume of products at high speeds—the key to making this process as seamless as possible are Right Angle gear reducers.

Charlie Ritinski, Chief Product & Innovation Manager at Sumitomo Drive Technologies, explains that "Right Angle gear reducers save space, reduce structural costs and increase safety. When the shaft-mounted reducer is a directly connected right angle bevel unit, significant gains in operating efficiencies, typically 5% to 10% or more, as well as reduced maintenance expenses, can be achieved."

In his whitepaper titled Reducer Shaft Mounting Systems, Charlie takes a deeper dive into the relative merits of five basic methods of mounting speed reducers directly onto a drive or head shaft. The methods explained include; keyed, splined, taper grip bushing, shrink disc, and rigid coupling and can be read here.

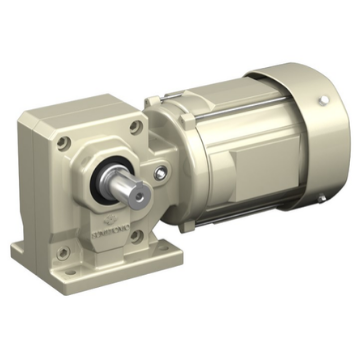

Sumitomo gear reducers convey quality and efficiency and are built to last. We supplied our first unit into a parcel handling facility back in 1974, and now we help move thousands of miles of conveyors each day. Here are our top two right angle gear reducers used in the Material Handling industry.

- Cyclo® Bevel Buddybox (BBB) 4 Series

- Power 1/8 to 60 HP

- Ratio 11:1 to 26,000:1 (and greater)

These right-angle options for conveyor drives allow for mounting flexibility and require limited maintenance, with available "no maintenance" options. Quill input and standard C-Face designs are also available. With Bevel Buddybox (BBB) gear reducers, there are no V-belt drives or associated guards to maintain, replace, or cause safety hazards. They also feature double output seals for leak-free operation and optimal protection from lubrication contamination.

This St. Patrick's Day, conveyors will keep the beer flowing to your local market, but Sumitomo will make sure the conveyors never stop. When your business demands reliability and speed, choose us to keep your operation moving.

Cheers!