Servo Bevel BuddyBox

Maximizing Torque, Optimizing Control.

The Cyclo BBB4 Servo Gearbox is a right angle servo gearbox with a unique combination of features that result in a highly reliable, efficient, and durable gearbox. The all-steel internal construction, Cyclo® or planetary gear inputs and the ductile iron housing, provide unmatched ruggedness.

- 100% Hardened Steel Components

- Oversized, single-piece pinion provides 300% momentary shock-load.

- Up to 4,000 RPM Input Speed

- Up to 159,983 N•m (18,076 lb•in) IN Torque

- Ratio Range 11:1 up to 26,000:1 and greater

| Input | Integral gearmotor, quill and C-face adapter |

| Output | Shrink Disc, Taper-Grip® Bushing, Solid Shaft, Keyed Hollow Bore, Screw Conveyor |

| Mounting | Hollow Shaft, Foot, Flange, U-Face (direct surface mount) |

| Sizes | 6 frame sizes (A-F), 48 to 1059 kg |

| Ratios | 11 to 26,000 and greater |

| Power Range | 0.10kW to 75kW (1/8HP to 75HP) |

| Torque Capacity | Up to 17,400 N·m (159,983 lb·in) |

| Motor Standards | NEMA, IEC, JIS, UL, CSA, CE |

What Makes the BBB4 Right Angle Servo Gearbox Different?

Cyclo BBB4 Right Angle Servo Gearboxes are designed to offer high precision and efficiency, with minimal backlash and high torque capacity--which is essential for applications requiring precise positioning and motion control.

It is compatible with NEMA, IEC, JIS, UL, CSA, and CE motor standards, making it suitable for diverse industrial applications.

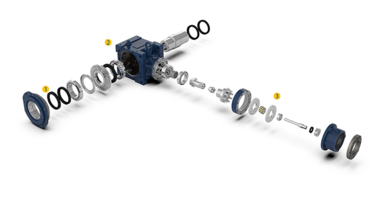

Add Exploded Image, but # the parts with descriptions. The image seems wide so maybe use 1 column and a table underneath OR a 2 column with 2/3 photo and 1/3 copy.

More About Right Angle Servo Gearboxes

Right Angle Spiral Bevel Servo Gearboxes use spiral bevel gears to transmit power at a 90-degree angle with enhanced efficiency and precision. These gearboxes are designed for applications requiring accurate torque transmission and high-speed capabilities in compact spaces. The spiral bevel gears offer smoother operation and lower noise compared to straight bevel gears, making them suitable for high-precision industries like robotics, aerospace, and automation. Their design ensures reliable performance and longevity, even in demanding operational conditions.

- Seals

- Ductile Iron Housing

- Cyclo Disc

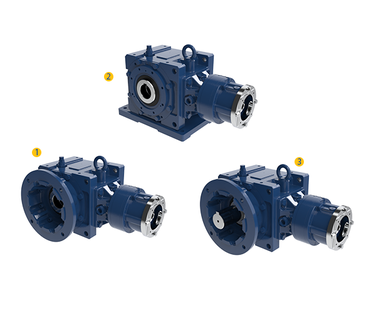

Available Mounting Options

- Flange

- Foot

- U-Face

Available Input & Output Options

- Taper-Grip Bushing

- Shrink Disc

- Solid Shaft

- Clamp Ring

- Key Hollow Bore

Advantages of Right-Angle Spiral Bevel Servo Gearboxes

This guide covers everything from alignment, motor installation, and safety protocols for servo gearbox operation.

Read about the advantages of industrial gearboxes in servo systems, and why they are the choice to enhance automation processes.

Learn about the different warning signs for servo gearmotors so you can face various mechanical issues in your operation.

Find out what are the 10 requirements you need to know before you purchase your new servo gearbox.

What makes a right-angle servo gearbox different than other servo gearboxes?

Space Efficiency: One of the most significant advantages of right-angle servo gearboxes is their ability to fit into tight spaces where other gearboxes might not. The 90-degree angle between the input and output shafts allows for more versatile mounting options and efficient use of space, particularly important in compact machinery designs and when retrofitting equipment.

Direct 90-Degree Power Transmission: In applications that require the direction of the drive to be changed by 90 degrees, a right-angle gearbox does this inherently without needing additional components or complex configurations. This direct approach reduces the potential for efficiency losses and mechanical issues that might arise from more complicated setups.

High Precision and Low Backlash: Many right-angle servo gearboxes are designed to offer high precision and low backlash, which is crucial for applications requiring accurate positioning and control, such as in robotics, CNC machinery, and automation systems.

Ease of Integration with Servo Motors: Right-angle servo gearboxes are specifically designed to work seamlessly with servo motors, providing a straightforward solution for integrating motion control systems. This ease of integration simplifies the design and implementation process for engineers and designers.

Documentation

For more technical information, download our Advanced Gearboxes Catalog here.

Frequently Asked Questions (FAQs)

Here is a list of frequently asked questions (FAQs) about right angle servo gearboxes and their answers.

What is a right-angle servo gearbox?

What is a right-angle servo gearbox?

A right-angle servo gearbox is a mechanical device that transmits power from a servo motor to a driven component at a 90-degree angle, optimizing space and design flexibility in various applications.

How does it differ from inline servo gearboxes?

How does it differ from inline servo gearboxes?

Unlike inline gearboxes where the input and output shafts are aligned, right angle gearboxes change the direction of the drive train by 90 degrees, allowing for more compact and versatile machine designs.

Can it be customized for specific applications?

Can it be customized for specific applications?

Yes, many manufacturers offer customization options for gear ratios, shaft configurations, and mounting solutions to meet specific application requirements. Find our more about our custom gearbox replacement here.

What factors determine the compatibility of a right angle servo gearbox with my servo motor?

What factors determine the compatibility of a right angle servo gearbox with my servo motor?

Compatibility depends on the gearbox's input shaft size, mounting flange specifications, and the torque handling capacity. Ensure the gearbox matches your motor's physical dimensions and operational parameters.

How does backlash affect the performance of a right angle servo gearbox, and what levels are typically acceptable?

How does backlash affect the performance of a right angle servo gearbox, and what levels are typically acceptable?

Backlash, or play between gear teeth, can impact precision in positioning applications. Acceptable levels vary, but for high-precision tasks, look for gearboxes with minimal backlash specifications, often less than 5 arc-minutes.

Are there specific lubrication requirements for right angle servo gearboxes?

Are there specific lubrication requirements for right angle servo gearboxes?

Yes, the type and frequency of lubrication depend on the gearbox design and application environment. Manufacturers often recommend specific lubricants and maintenance schedules to ensure optimal performance and longevity.

Can right-angle servo gearboxes operate in extreme environments?

Can right-angle servo gearboxes operate in extreme environments?

Some gearboxes are designed for harsh conditions, including high or low temperatures, corrosive atmospheres, and washdown applications. Check the product's IP rating and material construction for suitability.

What's the process for selecting the correct gear ratio for my application?

What's the process for selecting the correct gear ratio for my application?

Selecting the correct gear ratio involves understanding your application's speed and torque requirements. A higher gear ratio increases torque but reduces speed, and vice versa. Calculation tools or consultations with manufacturers can assist in making the right choice.

How do I interpret the torque rating of a right-angle servo gearbox?

How do I interpret the torque rating of a right-angle servo gearbox?

The torque rating indicates the maximum continuous torque the gearbox can handle. It's essential to choose a gearbox whose rating exceeds the peak torque demands of your application to avoid overload and potential failure.

What are the signs that a right angle servo gearbox needs maintenance or replacement?

What are the signs that a right angle servo gearbox needs maintenance or replacement?

Indicators include increased noise or vibration, decreased performance or precision, and visible wear or leakage. Regular inspections can help identify issues early and extend the gearbox's service life.

MOBIL SHC™ GEAR HI-SHOCK 150

MOBIL SHC™ GEAR HI-SHOCK 150

- High-Performance Synthetic Lubricant

- Available for Cyclo® Products

- Extends the Life up to 3 Times

- Available 3-Year Warranty

Related Servo products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.