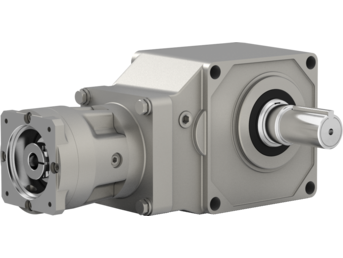

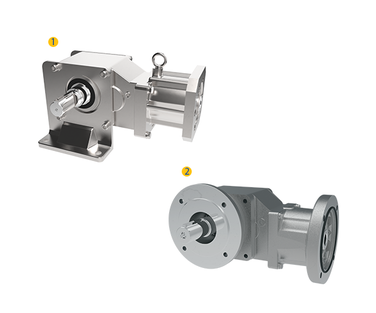

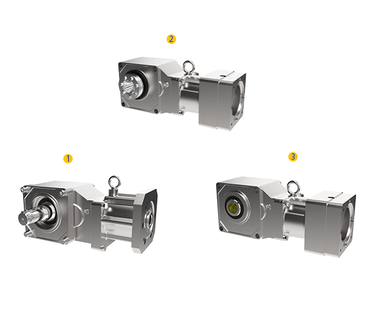

Servo Hyponic®

Optimized For All Servo Motors in the Market

This right angle hypoid servo gearbox features a compact, modular housing, maintenance-free grease lubrication and boasts a gear efficiency of up to 93% across all ratios. It is available with various options, including grease lubrication, antibacterial coating, waterproofing, and low-temperature requirements.

- Maintenance-free grease lubrication eliminates oil changes

- Up to 3,600 RPM Input Speed

- Up to 13,100 N•m (1,480 lb•in) in Torque

- Ratio Range from 5:1 up to 1,440:1

- Clamp Ring Input

| Output Shaft | Hollow shaft, Solid shaft |

| Output Shaft Direction(s) | Any Mounting Direction |

| Mounting Style | Foot mount, Flange mount |

| Frame Size | 4 sizes |

| Reduction Ratio | 5:1 - 60:1 |

| Motor Types | Optimized for all servo motors on the market |

What Makes our Right Angle Hypoid Servo Gearbox Different?

The Servo Hyponic is a maintenance-free, high-efficiency right angle hypoid gearbox designed for motion control applications. Available in 12 sizes with reduction ratios from 5:1 to 1440:1, it supports various mounting styles and shaft configurations. The product is suitable for diverse industry applications, offering options like antibacterial coating and waterproofing for specific requirements.

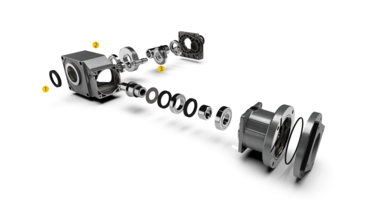

- Seals

- Housing

- All-steel Hypoid Gearing

Available Mounting Options

- Foot Mount

- Flange

Available Input & Output Options

- Plug-In Shaft

- Shrink Disc

- Keyed Hollow Bore

- Clamp Ring

Superior Packages to Protect Your Operation with Shield 360

Unmatched Solutions for the Food Processing Industry

Sumitomo Drive Technologies specializes in providing drive solutions that enhance operational efficiency for the Food & Beverage manufacturing industry.

Our products are engineered to meet the specific demands of production environments, focusing on reliability, energy efficiency, and compliance with industry standards. With a deep understanding of the challenges faced by manufacturers today, we offer tailored solutions designed to improve throughput, minimize downtime, and support continuous operation.

More About Right Angle Hypoid Servo Gearboxes

Right angle hypoid servo gearboxes are precision mechanical devices designed to transmit power and motion between axes at right angles (90 degrees) efficiently and with high accuracy. They are an essential component in various industrial and robotic applications where precise control and movement are critical.

Advantages of Right Angle Hypoid Servo Gearboxes

This guide covers everything from alignment, motor installation, and safety protocols for servo gearbox operation.

Read about the advantages of industrial gearboxes in servo systems, and why they are the choice to enhance automation processes.

Learn about the different warning signs for servo gearmotors so you can face various mechanical issues in your operation.

Find out what are the 10 requirements you need to know before you purchase your new servo gearbox.

For more technical information, download our Advanced Gearboxes Catalog here.

Frequently Asked Questions (FAQs)

Here is a list of frequently asked questions (FAQs) about inline servo gearboxes and their answers.

What is a Right Angle Hypoid Servo Gearbox?

What is a Right Angle Hypoid Servo Gearbox?

A gearbox that combines hypoid gears and servo motor compatibility for precise control in a compact design, transmitting power at a 90-degree angle.

How does a Hypoid Gear differ from a Bevel Gear?

How does a Hypoid Gear differ from a Bevel Gear?

Hypoid gears have an offset axis, allowing for larger contact surfaces and higher torque transmission than traditional bevel gears, with reduced noise and vibration.

Why are they used in servo applications?

Why are they used in servo applications?

Their precision, efficiency, and ability to handle varying speeds and torque make them ideal for applications requiring exact motion control.

What are the main applications of these gearboxes?

What are the main applications of these gearboxes?

Used in robotics, automation, packaging machinery, and anywhere precise, efficient motion control is needed in a compact space.

What are the advantages over other gearbox types?

What are the advantages over other gearbox types?

They offer high torque capacity, compact design, high efficiency, and operate more quietly and smoothly.

Can they be used in food and beverage applications?

Can they be used in food and beverage applications?

Yes, with appropriate coatings and waterproofing, they are suitable for hygienic environments like food and beverage processing.

How does the hypoid design enhance efficiency in servo applications?

How does the hypoid design enhance efficiency in servo applications?

The hypoid design allows for larger gear-tooth contact, reducing slippage and increasing efficiency by transmitting higher torque smoothly and quietly, ideal for precise servo control.

What are the key factors to consider when selecting a Right Angle Hypoid Servo Gearbox?

What are the key factors to consider when selecting a Right Angle Hypoid Servo Gearbox?

Consider torque requirements, speed, ratio, space constraints, and compatibility with the servo motor to ensure optimal performance and integration.

Can Right Angle Hypoid Gearboxes be customized?

Can Right Angle Hypoid Gearboxes be customized?

Yes, they can be tailored to meet specific application needs, including gear ratios, shaft configurations, and mounting options.

What are the typical maintenance requirements?

What are the typical maintenance requirements?

They require less maintenance than other types, usually involving regular inspections and ensuring proper lubrication to prolong lifespan and maintain efficiency.

What role does the gear ratio play?

What role does the gear ratio play?

Gear ratio affects the torque output and speed, essential for matching the gearbox performance to the application's requirements.

How do they contribute to noise reduction?

How do they contribute to noise reduction?

The hypoid gear design operates more smoothly and quietly than other gears, reducing noise in sensitive environments.

How do they compare to Worm Gearboxes?

How do they compare to Worm Gearboxes?

Hypoid gearboxes are more efficient and can transmit higher torque than worm gearboxes, with better energy savings and performance

Related Servo products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.