Fine Cyclo A-Series F2 Type

Compact all-rounder high precision gearbox

All-rounder for all available automation tasks. Compact cylindrical housing.

- Less than 1 arcmin Lost Motion

- Fully sealed and ready to use

- Maintenance free for life

- 5 different ratios available (depending on size)

- Many different input shaft styles and types possible

- Motor adapter on request

Variants:

- F2C-A cylindrical housing

- F2CF-A flange housing

Input Shaft Variants:

- Keyway

- Clamp Ring

- Spline

| Zero Mechanical Backlash | |

| Lost Motion | <1 arcmin |

| Number of Sizes | 4 |

| Reduction Ratios | 29:1 / 59:1 / 89:1 / 119:1 / 179:1 (availability depending on size) |

| Nominal Torque | 149 Nm up to 1390 Nm |

| Acceleration Torque | 335 Nm up to 2910 Nm |

| Max. Momentary Peak Torque | 785 Nm up to 7210 Nm |

| Input speed | up to 6150 rpm |

| Max. Bending Moment | 608 Nm up to 2550 Nm |

| Bending Stiffness | 230 Nm up to 1600 Nm |

| Axial Load | 3920N up to 11800N |

| Torsional stiffness | up to 445 Nm/arcmin |

Key Product Facts

Advantages of Fine Cyclo A-Series

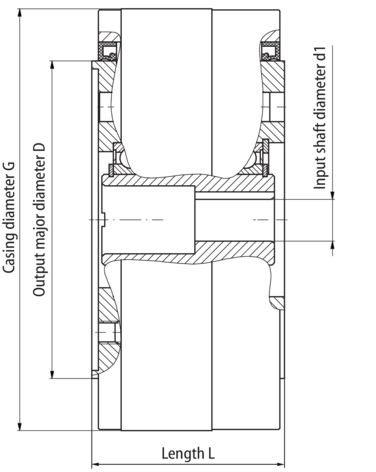

Main dimensions and mass

| Size | Length L [mm] | Diameter G [mm] | Diameter D [mm] | Diameter d1 (1) [mm] | Mass [kg] |

|---|---|---|---|---|---|

| A15 | 65.5 | 126 | 90 | 14 | 5 |

| A25 | 70 | 156 | 114 | 22 | 7.3 |

| A35 | 85 | 186 | 140 | 30 | 13 |

| A45 | 101 | 231 | 174 | 38 | 24 |

Diameter G = Casing diameter

Diameter D = Output major diameter

Diameter d1 = Input shaft diameter

(1) maximum values, adjusted to customer motor

Torque and Speed main data

| Size | Nominal output torque (1) [Nm] | Accel. / decel. torque [Nm] | Mean input speed (2) [rpm] | Max input speed [rpm] | |

|---|---|---|---|---|---|

| A15 | (i 59, 89) | 149 | 335 | 5600 | 6150 |

| A25 | (i 29) | 283 | 721 | 3100 | 4350 |

| (i 59...119) | 349 | 4200 | 5050 | ||

| A35 | (i 29) | 499 | 1390 | 2500 | 3500 |

| (i 59...119) | 668 | 3300 | 3950 | ||

| A45 | (i 29) | 1060 | 2910 | 1900 | 2700 |

| (i 59...179) | 1390 | 2600 | 3150 | ||

(1) at input speed n1=1500 rpm

(2) at 50% ED

Output bearing capacity

| Size | Max permissible bending moment [Nm] | Max permissible axial load push / pull [N] |

|---|---|---|

| A15 | 608 | 3920 / 2450 |

| A25 | 1030 | 3920 / 2450 |

| A35 | 1620 | 7850 / 5400 |

| A45 | 2550 | 11800 / 6870 |

Available ratios

| Size | Ratios |

|---|---|

| A15 | 59 / 89 |

| A25 | 29 / 59 / 89 / 119 |

| A35 | 29 / 59 / 89 / 119 |

| A45 | 29 / 59 / 89 / 119 / 179 |

Above technical specifications are intended for rough preselection only.

CAD Downloads

Get our latest CAD files for your construction.

Please contact us for specific motor adaption and other customization:

How often does the Fine Cyclo® require maintenance?

Customers should never open the Fine Cyclo. The reduction stages of the FA-Series reducers are lubricated for life. Additionally, their internal components are matched in such a way that makes re-assembly very difficult for untrained personnel. If desired, customers may return Fine Cyclos to Sumitomo for grease replenishment after 5 years in order to increase service life.

Related Fine Cyclo® products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.