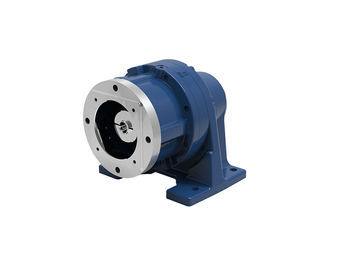

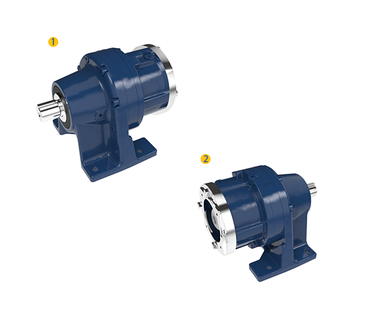

Cyclo Inline Servo Gearbox

Power Meets Precision, Every Revolution

-

Explore the precision and efficiency of Sumitomo Cyclo Inline Servo Gearboxes. Designed for seamless integration and optimal performance in demanding applications, our gearboxes offer unmatched durability and control.

-

This Inline Servo Gearmotor is available with Standard Backlash or Low Backlash

-

500% Momentary Shockload

-

Up to 4,000 RPM Input Speed

-

Up to 603,000 N•m(68,130 lb•in) IN Torque

-

Ratio Range from 6:1 up to 658,503:1

- Standard-Backlash Series

| Allowable Peak Torque | Up to 12,125 lb-in (29.7 - 1370 N⋅m) |

| Motor Capacity | 0.2 kW - 9.0 kW |

| Output Shaft Direction(s) | Any Mounting Direction (horizontal, vertical downward, vertical upward) |

| Mounting Style | Foot Mount, Case mount, Flange Mount |

| Frame Size | 12 sizes |

| Reduction Ratio | 6:1 - 87:1 |

- Low-Backlash Series

| Backlash | 6 arc min(12 arc min for reduction ratio 6) |

| Allowable Peak Torque | Up to 5,575 lb-in (29.7 - 630 N⋅m) |

| Motor Capacity | 0.2 kW - 5.0 kW |

| Output Shaft Direction(s) | Any Mounting Direction |

| Mounting Style | Foot Mount, Case mount, Flange Mount |

| Frame Size | 4 sizes |

| Reduction Ratio | 6:1 - 29:1 |

What Makes the Cyclo Inline Servo Gearbox Different?

Sumitomo’s Cyclo® technology coupled with innovative product options and accessories offer the most extensive range of application solutions available.

- Seals

- Housing

- Cyclo Disc

Available Mounting Options

- "H" Foot

- V-Flange

- F-Flange

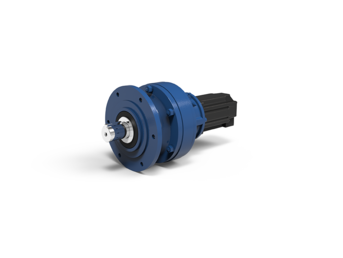

Available Input Options

- Clamp Ring

- Key Hollow Bore

With Cyclo Technology Built In, The Options Are Endless

500% Momentary Shockload

The Cyclo® design in this inline servo gearbox spreads the load across 2/3 of the reduction components, enabling the units to absorb and dissipate shocks better than typical concentric servo drives.

More About Inline Servo Gearboxes

Inline cycloidal servo gearboxes are a specialized type of gearbox known for their high precision, robustness, and distinctive mechanism of action, which differentiates them from other gearbox types. Their design is based on the principles of cycloidal motion, offering unique advantages in certain applications.

Inline servo gearboxes enhance system performance by seamlessly integrating with servo motors, ensuring reliable and precise operation in various demanding environments.

Advantages of Inline Cycloidal Servo Gearboxes

This guide covers everything from alignment, motor installation, and safety protocols for servo gearbox operation.

Read about the advantages of industrial gearboxes in servo systems, and why they are the choice to enhance automation processes.

Learn about the different warning signs for servo gearmotors so you can face various mechanical issues in your operation.

Find out what are the 10 requirements you need to know before you purchase your new servo gearbox.

What makes an inline servo gearbox different than other servo gearboxes?

Inline servo gearboxes distinguish themselves from other types of servo gearboxes (hyperlink servo gb to pillar page) primarily through their configuration and alignment with the motor. Here are the key differences that set inline servo gearboxes apart:

Configuration

Inline Design: The most distinctive feature of inline servo gearboxes is their design, which places the output shaft in direct line with the motor shaft. This configuration results in a more compact and efficient setup, as the gearbox can directly transmit power without additional components or angular conversions.

Space Efficiency

Compact Footprint: Due to their straight-line configuration, inline servo gearboxes occupy less space. This makes them particularly suitable for applications with limited space or where a streamlined assembly is crucial.

Torque Transmission

Direct Torque Transmission: An inline servo gearbox efficiently transmits torque from the motor to the driven component without the losses that might occur in setups where the gearbox and motor are not aligned. This direct transmission ensures minimal mechanical losses and maximizes efficiency.

Integration Ease

Ease of Integration: Inline servo gearboxes can be more straightforward to integrate with various motors and machinery due to their linear design. This ease of integration simplifies the engineering process for systems requiring high precision and alignment.

Documentation

Download PDF files for the latest installation, operation, and maintenance manuals.

For more technical information, download our Advanced Gearboxes Catalog here.

Frequently Asked Questions (FAQs)

Here is a list of frequently asked questions (FAQs) about inline servo gearboxes and their answers.

What is an inline servo gearbox?

What is an inline servo gearbox?

An inline servo gearbox is a type of gear system designed to offer precise speed, torque, and direction control in automation systems. Its defining characteristic is the alignment of the output shaft with the motor shaft, leading to a compact and efficient design ideal for various applications.

How do inline servo gearboxes differ from other types of gearboxes?

How do inline servo gearboxes differ from other types of gearboxes?

The key difference lies in the configuration; inline servo gearboxes have a direct line alignment between the motor and output shaft, making them more compact and efficient for transmitting power directly. This contrasts with other types, such as right-angle gearboxes, which change the direction of the output shaft relative to the motor.

What are the advantages of using an inline servo gearbox?

What are the advantages of using an inline servo gearbox?

Advantages include a compact and efficient design, precise control over motion with minimal mechanical losses, higher torque transmission efficiency, and ease of integration into various systems due to their straightforward alignment and mounting.

In what applications are inline servo gearboxes most commonly used?

In what applications are inline servo gearboxes most commonly used?

They are widely used in robotics, aerospace, packaging machinery, and automation systems—essentially in any application requiring precise control over motion in a compact space.

Can inline servo gearboxes be customized for specific applications?

Can inline servo gearboxes be customized for specific applications?

Yes, many manufacturers offer customization options for inline servo gearboxes, including gear ratios, output torque, and shaft configurations, to meet the specific requirements of different applications.

How do I choose the right inline servo gearbox for my application?

How do I choose the right inline servo gearbox for my application?

The selection depends on several factors, including the required torque, speed, precision, and space constraints. Consulting with manufacturers or distributors with detailed specifications of your application can help identify the most suitable gearbox.

How are inline servo gearboxes maintained?

How are inline servo gearboxes maintained?

Maintenance typically involves regular inspections, lubrication, and checking for wear and tear. The specific maintenance schedule and procedures can vary based on the gearbox model and application conditions, so it's important to refer to the manufacturer's guidelines.

What is the lifespan of an inline servo gearbox?

What is the lifespan of an inline servo gearbox?

The lifespan can vary widely depending on the application, load, operating conditions, and maintenance practices. Generally, with proper maintenance, inline servo gearboxes can have a long service life, often matching or exceeding the lifespan of the servo motor to which they are attached.

MOBIL SHC™ GEAR HI-SHOCK 150

MOBIL SHC™ GEAR HI-SHOCK 150

- High-Performance Synthetic Lubricant

- Available for Cyclo® Products

- Extends the Life up to 3 Times

- Available 3-Year Warranty

Related Servo products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.