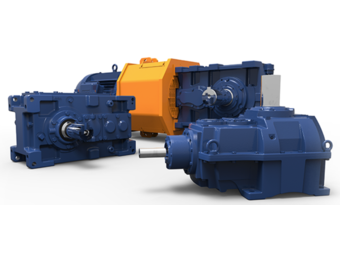

Gear Reducers

Gear reducers, also known as speed reducers, are built to deliver the kind of reliability, durability, and performance that industrial operations depend on every day. They’re the quiet workhorses behind countless machines, helping power everything from manufacturing lines to heavy-duty equipment.

As a global leader in power transmission, Sumitomo Drive Technologies continues to raise the bar with smart designs and high-quality engineering that keep things moving smoothly.

So, what exactly is a speed reducer? It's a mechanical device that increases torque by reducing the speed of a power source, making the output more useful for industrial tasks. Choosing the right speed reducer comes down to your specific project and application needs.

Our gear reducers are built for the future—delivering power and performance where it matters most.

Our Best Selling Reducers

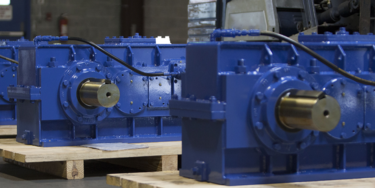

Sumitomo Drive Technologies offers a full lineup of speed reducers with the gear ratios, torque, and horsepower to help optimize your operation. With manufacturing facilities in Virginia, Illinois, Texas, and California, we design, build, and ship our high-performance reducers across the U.S.

If your project calls for something outside of our standard options, we can engineer a custom solution to meet your exact requirements.

But Sumitomo Drive Technologies delivers more than just solid specs. Our speed reducers are backed by decades of expertise and built to give you lasting peace of mind. Whether you're developing new equipment or upgrading an existing system, our team will help you find a power transmission solution that's reliable, efficient, and built for convenience.

Designed for applications where downtime isn’t an option, our gear reducers deliver consistent performance when it matters most.

What Makes Sumitomo Speed Reducers Different?

-

Innovative Design: Sumitomo continually invests in R&D to create innovative designs that improve upon traditional gear reducer technology. This makes their gear reducers some of the most advanced on the market.

-

Excellent Support and Service: Sumitomo provides excellent customer service, including technical support, maintenance, and repair services. This ensures your gear reducer performs optimally throughout its lifespan.

-

Durability: Sumitomo gear reducers are built for longevity. Their robust design and construction ensure they can withstand demanding industrial environments, providing value for years to come.

-

Integration with IIoT: Modern Sumitomo gear reducers often feature smart technology that can be integrated into the Industrial Internet of Things (IIoT), enabling real-time monitoring and predictive maintenance for increased operational efficiency.

Frequently Asked Questions

Whether you're wondering about the fundamental workings of these integral mechanical devices, curious about the leading-edge Sumitomo gear reducers, or interested in how these tools interface with the realm of the Industrial Internet of Things (IIoT), our FAQ section has you covered. Designed with your inquiries in mind, this section provides in-depth responses to a wide array of commonly asked questions. Read on to gain a wealth of knowledge about gear reducers and speed reducers and how they continue to revolutionize efficiency across various industries.

What is a Speed Reducer or Gear Reducer?

What is a Speed Reducer or Gear Reducer?

A gear reducer is a mechanical device that reduces the speed of a motor's output while increasing torque. This change in speed-to-torque ratio allows machines to operate more efficiently and safely.

How does a speed reducer work?

A speed reducer works by taking the output speed of a motor and reducing it through gear ratios. This reduced speed output generates greater torque, enabling machinery to perform tasks requiring high force at lower speeds.

What's the difference between a gear reducer and a speed reducer?

What's the difference between a gear reducer and a speed reducer?

Essentially, these terms are often used interchangeably as both refer to devices that alter the speed and torque output of a motor. However, some industries might prefer one term over the other based on specific applications.

What are the benefits of using a Sumitomo gear reducer?

What are the benefits of using a Sumitomo gear reducer?

Sumitomo gear reducers are known for their reliability, efficiency, and durability. They offer superior performance and are crafted using cutting-edge technology, which makes them suitable for a wide range of industrial applications.

In what industries are speed reducers used?

Speed reducers are used across various industries, including manufacturing, mining, agriculture, food processing, and more. They are essential components in any sector where machinery requires variations in speed and torque.

How do I select the right gear reducer for my needs?

How do I select the right gear reducer for my needs?

When selecting a gear reducer, consider factors such as the required speed and torque output, the operating environment, and the type of motor or machinery it will be connected to. Consultation with a technical expert or manufacturer is recommended.

What are the different types of gear reducers?

Gear reducers come in several types, including worm, helical, bevel, planetary, and more. Each type has its unique characteristics and is suitable for different applications.

Can gear reducers be used in high-temperature environments?

Can gear reducers be used in high-temperature environments?

While gear reducers can handle a range of operating conditions, extremely high temperatures may affect their performance and lifespan. Special high-temperature gear reducers are available for such environments.

How do I maintain my Sumitomo speed reducer?

How do I maintain my Sumitomo speed reducer?

How do I maintain my Sumitomo speed reducer?

Regular inspection, lubrication, and replacement of worn parts are key to maintaining your speed reducer. Always follow the manufacturer's guidelines for maintenance.

What happens if a gear reducer fails?

Failure of a gear reducer can lead to a reduction in machinery efficiency, excessive noise, and even machinery breakdown. Regular maintenance and inspections can prevent most failures.

Where can I buy Sumitomo gear reducers?

Sumitomo gear reducers can be purchased through authorized distributors or directly from Sumitomo. Request a quote or reach out to a Sumitomo representative at any time.

Are Sumitomo speed reducers customizable?

Yes, Sumitomo offers custom solutions to meet unique operational requirements in different industries.

How long does a Sumitomo gear reducer last?

How long does a Sumitomo gear reducer last?

With proper maintenance and under normal operating conditions, Sumitomo gear reducers can last for many years. The exact lifespan depends on usage and environmental factors.

How energy efficient are Sumitomo gear reducers?

Sumitomo gear reducers are designed to deliver optimal efficiency, minimizing energy loss during operation. Their energy efficiency contributes to lower operational costs and a smaller environmental footprint.

How are gear reducers and speed reducers relevant to the Industrial Internet of Things (IIoT)?

Modern gear and speed reducers, like those from Sumitomo, often feature smart technology that can be integrated into the IIoT. This allows for real-time monitoring, predictive maintenance, and improved operational efficiency.

What are worm gear reducers?

What is a worm gear reducer?

Worm gear reducers, also known as worm gearboxes or worm speed reducers, are a type of gear system used to achieve high torque output while maintaining low rotational speed. It's characterized by its unique design that consists of a worm (a screw-like gear) and a worm wheel (a gear similar to a spur gear).

In a worm gear reducer, the worm is typically connected to the motor or another driver, and it rotates to drive the worm wheel. Due to the configuration and angle of the worm thread, the worm wheel cannot drive the worm. This feature provides a locking mechanism in many applications, preventing back-driving and enhancing safety.

Worm gear reducers are known for their compactness, high shock tolerance, and quiet operation. They are used in various applications, such as conveyor systems, lifts, gates, and heavy machinery, where significant torque is required at reduced speed.

Can I use a speed reducer for any application?

Can I use a speed reducer for any application?

Speed reducers, also known as gear reducers, play a critical role in various industries due to their ability to adjust a motor's speed to suit specific tasks. Here are some of the top applications for speed reducers:

-

Conveyor Systems: Speed reducers are integral components in conveyor systems used in industries like food processing, mining, and manufacturing. They help control the conveyor belt's speed, ensuring smooth and efficient operation.

-

Material Handling: Speed reducers are widely used in cranes, hoists, and other material handling equipment, where they enable precise control of lifting and moving heavy loads.

-

Pump Systems: In pump systems, speed reducers adjust the motor's speed to maintain the optimal flow rate, contributing to efficient and effective operation.

-

Agricultural Machinery: In agricultural equipment such as tractors, combines, and harvesters, speed reducers are crucial for controlling the machinery's operation, offering different speeds and torque levels for different tasks.

-

Food and Beverage Industry: Speed reducers are used in various machinery in the food and beverage industry, from mixers and grinders to packaging and bottling equipment.

Remember, the right speed reducer can significantly impact the efficiency and productivity of these applications, making it crucial to select one that best suits the specific requirements of each use case. Sumitomo speed reducers, known for their quality, reliability, and performance, are excellent choices for a broad range of applications.

Is a gear train the same as a gear reducer?

Is a gear train the same as a gear reducer?

While both a gear train and a gear reducer involve gears and the transfer of mechanical energy, they are not exactly the same thing.

A gear train refers to a group or sequence of gears connected in a specific arrangement. It can increase or decrease speed, change the direction of rotation, or move rotational motion to a different axis. The term 'gear train' simply describes the configuration of gears and doesn't specify whether the speed is being increased or reduced.

On the other hand, a gear reducer (also known as a speed reducer) is a specific type of gear train designed to reduce the speed of the input (usually from a motor) and increase torque. Gear reducers are used in many industrial applications where high torque at low speed is required.

So, in essence, a gear reducer is a type of gear train, but not all gear trains are gear reducers.

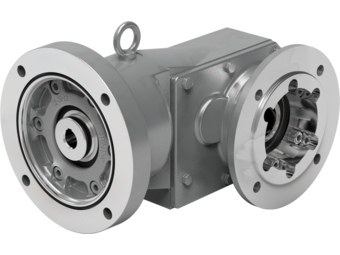

What are the different input shafts that Sumitomo reducers come in?

Whatever your specific requirements, whether space-saving gear reducers or a high-torque drive gear, there is a shaft arrangement that will meet them. We discuss concentric, parallel, and right-angle and the corresponding Sumitomo model in this blog.

Experience the Power of Sumitomo Reducers in your Application. With Sumitomo, The Options are Endless and Obtaining a Quote is Easy!

To accompany your next Sumitomo product, we offer various options and reducer accessories to lower your overall maintenance requirements, increase efficiency and increase your peace of mind. To receive a quote for your business, please complete our short website form with your name, email address, and a few more details, or reach out to our team of District Sales Managers.

Not in the United States? Sumitomo Drive Technologies is a worldwide company.

Find the link to the website for your specific country below.