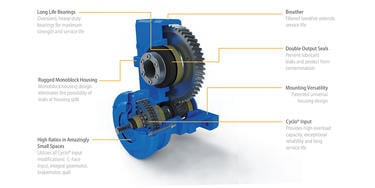

Cyclo® Helical BuddyBox Speed Reducer

Helical gearbox with Cyclo reducer input. Features keyless, Steel Taper-Grip® bushing for easy installation.

Offset parallel, helical gearbox in a rugged integral, shaft-mounted design.

- Integrated Cyclo® technology

- Keyless Taper-Grip® Bushing or Keyed Hollow Bore

- Ideal for Screw-Conveyor applications

| Input | Integral gearmotor, quill and C-face adapter |

| Output | Taper-Grip® Bushing, Keyed Hollow Bore, Screw Conveyor |

| Ratios | 11:1 up to 26,000:1 and greater |

| Torque | Up to 75,806 lb-in (8,565 Nm) |

| Power Range | 1/8-40 HP (0.1 to 30 kW) |

| Mounting | Hollow Shaft, Flange, Face |

| Options | Integral Motor, C-Face |

| Motor Standards | NEMA, IEC, JIS, UL, CSA, CE |

Cyclo® HBB

Sumitomo’s Cyclo® Helical Buddybox® (Cyclo® HBB) speed reducers and gearmotors provide innovative shaft-mounted drive solutions for demanding applications. The Cyclo® HBB combines the quiet, efficient and reliable performance of the Cyclo® input with the rugged helical-gear output. The modular design provides a compact, efficient product and the most flexible range of output speed and torque combinations available.

Key Facts

CAD / Configure

Select your level of product detail:

Learn more about our CONFIGURATOR TOOL:

FAQ

Do you have questions about the Cyclo HBB? Below are some of our most commonly asked questions, or you can view our Support area under Knowledge for more frequently asked questions and answers.

I don’t like the turnbuckle torque arms and sometimes have reversing applications they don’t work well for, do you have another option?

Yes, we have 6 different torque arm options to make your installation easy.

What if I need to change the backstop rotation?

No problem, your Sumitomo rep can assist with that, we can instruct you how, or you can send it to us to do.

I have a problem with backstops failing regularly, can a Cyclo® BBB4 fix that problem?

The BBB has a different design when it comes to the backstop.

- Our backstop is at the high-speed shaft achieving lift off easily and not creating drag and wear on the spragues

- Our backstop being at the high-speed shaft sees the least amount of torque. The combination of the backstop ratings being higher, and seeing less torque, results in a long life

- Our backstop is maintenance-free (no lubrication maintenance) and is sealed off from the reducer protecting the reducer from the backstop and the backstop from the reducer. There is no unified lubrication system between the two.

Can I adjust the speed with a direct drive like I can with a belt drive?

Not by changing a sheave size since that component is eliminated, but there are things to consider…

- How often are you really changing the speed?

- The flexibility of changing a sheave size also puts your system at risk. Are you overspeeding beyond the reducer's capabilities? Are you slowing down too much and causing the backstop spragues to drag and wear?

If you are utilizing a VFD, that can control your speed.

- If you find out you truly need to change your speed, our BBB is the only direct drive on the market that has a Cyclo cartridge that could be changed to change your overall speed eliminating the need for a whole new reducer. Work with your Sumitomo rep to consider this.

My motor is a footed motor on my belt drive system, do I have to get a new motor for the direct drive?

No, you can order a c-face transition kit from your motor manufacturer and turn a footed motor into a c-face motor very easily. We have other options we can provide if you absolutely can not replace or change your motor to a c-facemotor.

My belts are my weak spot, what is the weak spot in a direct drive?

Our BBB (for typically 50hp and under depending on ratio) is designed for momentary high shock load – higher than any direct drive in the industry through utilizing our Cyclo technology. Another safeguard that can be put in place include the following:

- BBB’s are designed and sized where the motor would amp out before any damage would be done to the reducer

- Can adjust the motor heater for additional safety measures if desired

- A torque limiting or shear coupling could be used within the c-face adaptor as an additional safety measure if desired

I don’t have a very long shaft, can I still replace a belt drive with a direct drive?

Yes, if our standard Taper Grip Bushing requires more shaft than you have, we have a new Taper Grip Bushing option that needs an average of ½ the shaft length. When we size up the reducer you need, we can tell you how much shaft length you need for both options.

What should be some features or upgrades I should consider for the Aggregate, Sand and Cement industries?

Taconite Seals, Severe Duty or Desiccant Breather

What are service factors and how are they used?

In general, reducers and gearmotors are rated for specific conditions and operating requirements of the application by the use of AGMA-defined Service Factors. There are three AGMA load classifications for reducers: uniform (U), moderate shock (M) and heavy shock (H), and three AGMA load classifications for gearmotors: I, II, and III. Refer to our catalog for a list of AGMA load classifications. These Service Factors are used in the product selection process to adjust for the specific conditions and operating requirements of your application.

What is the difference in the mounting positions of the Cyclo® HBB?

The mounting positions for the Cyclo® HBB detail the position of the unit relative to the driven shaft. The mounting position effects how the unit is assembled and maintained (i.e., location of oil fill ports, type of lubrication, breather location, etc.). You must specify the mounting position at the time of order.

Related BuddyBox® products

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.