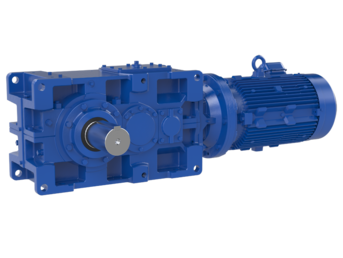

PARAMAX® 9000 Series Gearmotor

Featuring a compact design and optimized supply chain for fast delivery while maintaining high quality.

- Highly functional gearmotor available in 26 sizes and a wide range of options.

- Features high dedendum strength.Gearmotor with high load capacity, capable of withstanding strong impact loads.

- Newly designed cooling fan and cover. As a result: a major increase in the thermal rating.

- Housing structure can be mounted in any orientation: horizontal, vertical, or upright.

| Output Shaft | Hollow shaft, Solid shaft |

| Output Shaft Direction(s) | Horizontal, Vertical downward, Vertical upward |

| Mounting Style | Shaft mount, Case mount, Flange mount |

| Frame Size | 26 sizes |

| Reduction Ratio | Parallel Shaft 6.3:1 - 500:1 Right Angle Shaft 6.3:1 - 450:1 |

| Capacity | Up to 175Hp (132 kW) |

| Motor Types | Premium efficiency, for inverters, outdoors, increased safety, flameproof, compatible with global standards |

Product Features

26 sizes available, giving you the ability to select the best product for your needs.

This allows it to maintain good tooth contact, resulting in low noise.

There's power to spare, even under harsh environments and continuous operation.

It can accommodate all of your needs.

Direct motor coupling is now standard.

CAD Downloads

Get our latest CAD files.

Learn more about our CONFIGURATOR TOOL:

Frequently Asked Questions

Do you have questions about the Paramax® Drive? Below are some of our most commonly asked questions or you can view our Support area under Knowledge for more frequently asked questions and answers.

I have an application over 50hp that I want a direct drive for, do you have an option?

Yes, we have our Paramax which offers many ratios, right angle or offset parallel, many mounting options, many different output types, etc. Let us discuss further by contacting your Sumitomo rep!

I don’t like the turnbuckle torque arms and sometimes have reversing applications they don’t work well for, do you have another option?

Yes, we have 6 different torque arm options to make your installation easy.

What if I need to change the backstop rotation?

No problem, your Sumitomo rep can assist with that, we can instruct you how, or you can send it to us to do.

Can I adjust the speed with a direct drive like I can with a belt drive?

Not by changing a sheave size since that component is eliminated, but there are things to consider…

- How often are you really changing the speed?

- The flexibility of changing a sheave size also puts your system at risk. Are you overspeeding beyond the reducer's capabilities? Are you slowing down too much and causing the backstop spragues to drag and wear?

If you are utilizing a VFD, that can control your speed.

- If you find out you truly need to change your speed, our BBB is the only direct drive on the market that has a Cyclo cartridge that could be changed to change your overall speed eliminating the need for a whole new reducer. Work with your Sumitomo rep to consider this.

My motor is a footed motor on my belt drive system, do I have to get a new motor for the direct drive?

No, you can order a c-face transition kit from your motor manufacturer and turn a footed motor into a c-face motor very easily. We have other options we can provide if you absolutely can not replace or change your motor to a c-facemotor.

I don’t have a very long shaft, can I still replace a belt drive with a direct drive?

Yes, if our standard Taper Grip Bushing requires more shaft than you have, we have a new Taper Grip Bushing option that needs an average of ½ the shaft length. When we size up the reducer you need, we can tell you how much shaft length you need for both options.

What should be some features or upgrades I should consider for the Aggregate, Sand and Cement industries?

Taconite Seals, Severe Duty or Desiccant Breather

Are there drop bearing designs?

Yes.

What advantage does tooth form have on ratings?

A gear tooth, such as that of Paramax, with a 25-degree pressure angle provides for greater torque transmission due to its wider dedendum. It is also important in minimizing tooth breakage due to shock loading.

Are there single stage ratios available for Paramax®?

Yes, 1.25:1 thru 5:1 in the parallel shaft configuration; and 1.6:1 thru 4:1 in the right angle shaft configuration.

Enhance Your Industrial Operations with Sumitomo

Our industrial solutions set the standard in durability, efficiency, and innovation. Engineered to handle the toughest challenges, we are the reliable choice for your operations.